Bio-organic Fertilizer Spherical Granule Granulator Overview:

The bio-organic fertilizer spherical granule granulator manufactured by us adopts advanced technology to promise uniformly spherical shape of the end products. With large amounts of researches and experiments, we have overcome lots of problems during bio-organic fertilizer production, such as high-temperature sterilization, not smooth and slow dry of the existing bio-organic fertilizer granulator production.

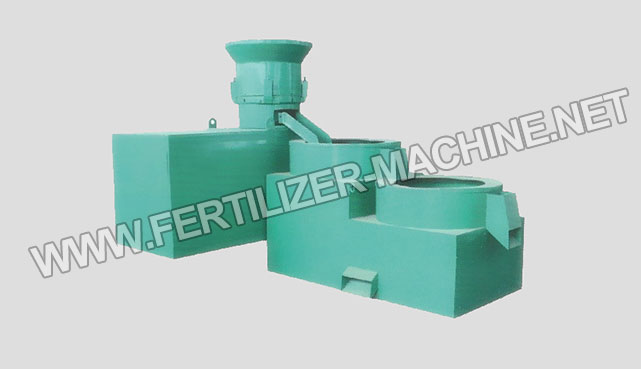

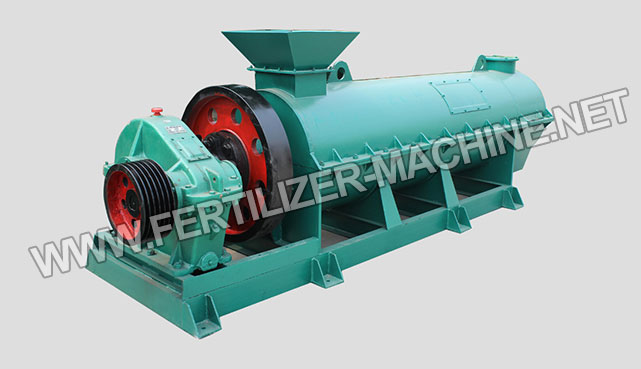

This granulator consists of two parts: flat die fertilizer granulator, and fertilizer polishing machine. Those two machines are combined together efficiently and conveniently, which makes uniformly-formed bio-organic fertilizer granule come true. With the new reasonable design, simple structure and unblocked particles bio-organic fertilizer ball granulating machine which can protect bacteria at normal temperature, our bio-organic fertilizer granulator is becoming more and more popular in the fertilizer industry. Our clients spoke high of it because of its excellent-function and high-efficiency. At the same time, this granulating machine can also be used in feed production, which fills the multi-usage of the domestic blank in granulator field.

Bio-organic Fertilizer Spherical Granule Granulator Features:

Our bio-organic fertilizer spherical granule granulator consists of flat die extrusion granulator and organic fertilizer polishing machine. As for flat die extrusion granulator, it is used for granulating organic materials after the fermentation process. It is considered as a more efficient way of fertilizer production at present. Equipped with various dies with a diameter ranging from 1.5mm to 20mm. Customers can choose whichever they like to produce organic fertilizer according to their raw materials.

Organic fertilizer polishing machine: It can make the cylindrical particles into spherical particles at one time. No returning materials are created and the granulation rate can reach as high as 98%.

Bio-organic Fertilizer Spherical Granule Granulator Application:

1.Using the peat,lignite, organic fertilizer sludge, straw as raw material to make the bio-organic granulation fertilizer granule.

2.Using the chicken manure as raw material to make organic granulation fertilizer granule.

3.Using soya-bean cake as raw materials to make the cake fertilizer

4.Using corn, beans, grass meal as raw material to make the mixed feed

5.Using the crop straw to make the bio-feed

Precautions for Using Bio-organic Fertilizer Spherical Granule Granulator:

1. Make sure that there are no hard things that are mixed in the raw materials, such as sands and irons. Rollers should be unleashed after it works for ten rounds(8 hours is 1 round). Then, add some heat-resistant greases to improve the capability of the rollers and prolong a longer service life.

2. Avoid the direct contact between the die and the rollers during the granulation process of the polishing machine.

3. If there is something wrong with the granulating or discharging process, unleash the die and cast the holes one by one. Then add some fiber materials before you restart the polishing machine.

4. The tightness of the belt should be examined regularly and frequently. Once an oil leakage in gearbox is found, you should change the gearbox in time.

Technical Data of Bio-organic Fertilizer Spherical Granule Granulator

| Model | ALCKP-40 | ALCKP-60 | ALCKP-80 |

| Productive capacity(t/h) | 1.8-2.5 | 2.5-3.5 | 4-5 |

| Granulation rate(%) | >95 | >95 | >95 |

| Granulation temperature(℃) | <30 | <30 | <30 |

| Granulation diameter(mm) | 3-30 | 3-30 | 3-50 |

| Power(kw) | 30 | 55 | 75 |

| Overall weight(kg) | 1200 | 1800 | 2500 |

| Practicality | Fertilizer, Feed | Fertilizer, Feed | Fertilizer, Feed |