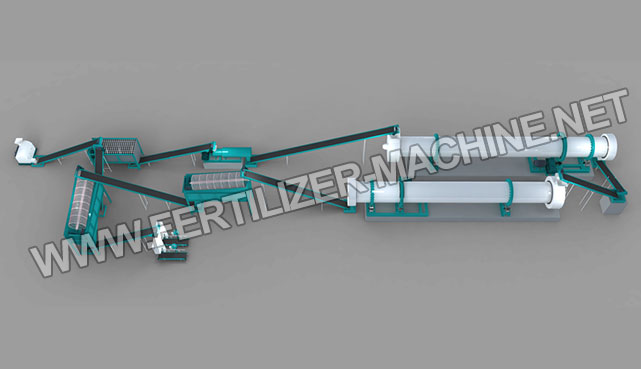

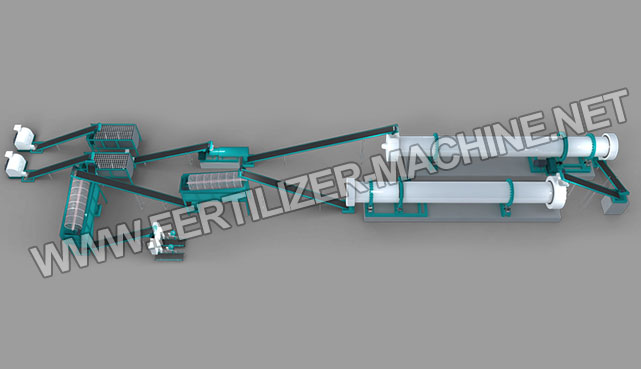

20,000 tons/year Compound Fertilizer Granulation Production Line Introductions:

This 20,000 Tons/Year Compound Fertilizer Granulation Production Line is a combination of a series of advanced equipment. It is featured with low production expenses and its high production efficiency. This production line can be used for granulating all kinds of compound raw materials. And the final fertilizer particles can be made with different concentrations according to your own needs, which can effectively supplement the necessary nutrients for crops and resolve the conflicts between the needs of crops and the supply of the soil.

Generally speaking, a compound fertilizer production line usually consists of these following parts: the mixing process, granulating process, drying process, cooling process, screening process, coating process and packaging process.

20,000 t/y Compound Fertilizer Granulation Production Line Main Components:

1. The Belt Weigher:

Firstly, we use the Belt Weigher to make the raw materials mixed according to a certain portion. This machine is highly automatic, so it can work more accurately and efficiently. What’s more, the levels of the belts can be changed according to the kinds of the raw materials.

2. Vertical Chain Crusher:

Assemble different compound raw materials according to a certain portion, and then put them into the Vertical Chain Crusher. The raw materials will be crushed into small particles so that they can meet the needs of the granulating process.

3. Disc Mixer:

After the raw materials are crushed, they will be sent into the Disc Mixer, in which the raw materials will be uniformly blended. The lining of the pan is made of polypropylene or stainless steel sheet, which helps improve the working efficiency as well as the production quality. Then the mixed materials will be sent into the Rotary Drum Granulator.

4. Rotary Drum Granulator:

The granulating process is the most important part of the whole production line. By adding a certain number of steams and vapors, the raw materials in the rotary drum will become uniformly humid during the granulation process. Then a series of chemical reactions will occur. In this machine, the fertilizer particles squeeze each other and roll into fertilizer particles. The uniformly formed fertilizer particles are of 3-4mm. After the granulation process, the particles will be sent into the Rotary Drum Drying Machine.

5. Rotary Drum Dryer:

During the drying process, the water contents of granulated particles will be dried, so that the particles will be harder and easier to store. The body of the machine is a slightly inclined rotary drum compared with the horizontal line. And the materials will be sent into the body from the higher end and compelled from the other end. The whole body is sealed, in which the materials will be contacted with the hot air with the continuous rotation of the drum. Then the next step is the cooling process.

6. Rotary Drum Cooler:

After the drying process, the temperature of the particles is a little high, so they need to be cooled before the packing process. This Rotary Drum Cooler adopts the most advanced cooling technology in the world and produces uniform particles, of which the temperature can be strictly controlled. Generally, the temperature of the particles is about 3-5 centigrade higher than the room temperature.

7. Rotary Drum Screening Machine:

After entering the Rotary Drum Screening Machine, the qualified particles will be sent into the coating machine, while the unqualified particles will be selected and then sent into the Vertical Chain Crusher to be granulated again.

8. Rotary Fertilizer Coating Machine:

The qualified particles will be coated by the Rotary Fertilizer Coating Machine, which will beauty the particles and strengthen their hardness at the same time. The Rotary Fertilizer Coating Machine adopts the special liquid material spraying technology and solid powder coating technology to prevent the caking of the fertilizer particles effectively.

9. Fertilizer Packaging Machine:

After the particles are coated, they will be packed by the Packing Machine. The Fertilizer Packing Machine is highly automatic, which makes the packing process more efficient and accurate.

10. Belt Conveyors:

Conveyors play the indispensable role in the production process, because it connects different parts of the whole production line. In this compound fertilizer production line, we choose to provide you with the Belt Conveyors. Compared with other kinds of conveyors, the Belt Conveyors have a larger coverage, which will make your production process more efficient and economic.

Advantages of the 20,000tons/year Compound Fertilizer Granulation Production Line:

1. This compound fertilizer production line is featured with low consumption, high production capacity and good economic benefit.

2. Designed with the compact and reasonable structures, the compound fertilizer production line will have a greater working capacity, which can be more suitable to the demands of the compound fertilizer production at present.

3. During the producing process, less energy is consumed and no three wastes are created. This compound fertilizer production line has a steady performance and reliable quality which prolongs a longer service life.

4. This compound fertilizer production line can be applied to producing all kinds of compound raw materials. And the granulation rate is high enough.

5. This compound fertilizer production line can be used to produce compound fertilizer with different concentrations, which can meet the needs of different customers.

Technical Data:

|

Product Item

|

Model

|

Motor Power

(kw) |

Production

Capacity(t/h) |

Weight

(t) |

Inclination

|

Dimension

L x W x H(mm)

|

|

Chain Crusher

|

ALCLP600

|

15

|

1-5

|

|||

|

Fertilizer Mixer

|

ALCPJ1800

|

7.5

|

4-6

|

1.4

|

1900*1812*1368

|

|

|

Rotary Drum Granulator

|

ALCZG1.6×6

|

11

|

5-8

|

12.0

|

2-2.5

|

700*320*310

|

|

Rotary Drum Dryer

|

ALCZG15150

|

15

|

5-7

|

2-5

|

Shell L x inner dia:

15000*1500 |

|

|

Rotary Drum Cooler

|

ALCLQ12120

|

7.5

|

2-5

|

Shell L x inner dia:

12000*1200 |

||

|

Rotary Drum

Screening Machine |

ALCGS1.2×4.5

|

3.0

|

3-5

|

2.5

|

2-2.5

|

Shell L x dia:

4500*1200 |

|

Rotary Drum

Coating Machine |

ALCBM1200×4000

|

5.5

|

~5

|

3

|

Shell L x inner dia:

4000*1200 |