Introduction of Anaerobic Digestion Digestate

Anaerobic digestion produces two main products: digestate and biogas. Anaerobic digestion (AD) digestate, also called biogas residue (slurry and dregs), is a nutrient-rich biofertiliser, being the organic product of microbial fermentation after producing biogas in methane-generating. All kinds of organic residues and waste, such as chicken dung, energy grasses, vegetable waste, malt husks, food waste, kitchen waste, Corn silage, grass silage, pig liquid manure, cattle liquid manure, old cooking oil, chip fat, flotation sludge, glycerin, slaughterhouse waste, could be the input materials of biogas plant, therefore, biogas residue is rich in organic matters, NPK elements, humic acids, vitamin, auxin and gibberellin, which are essential for optimal crop yields, making them high-grade bio fertilizers. It can well be used in agriculture to conserve and recycle nutrients and to reduce waste discharge and use of chemical fertilizers.

As we know, numerous different input substrates could be used as input materials of the biogas plant. Those materials varies with different nutrients. Energy crops, crop residues, waste paper, grass clippings, leftover food, sewage generally have greater DM content and more favourable nutrient composition than manure slurries, resulting in a more concentrated and valuable digestate.

Utilization of digestate

Seeing from the above picture: the solid or semi-solid material left over after AD is called digestate, while liquid exiting from the digester is called effluent. In some jurisdictions, digestate can be used directly, land-applied as fertilizer. In North America, it is more common to compost difestate or dry it for use as a fertilizer.

The treatment of the digestate to further increase its value and feasibility of transportation is necessary for governments and essential for environment. Because of its high concentration of nutrients, biogas residues are mostly used as agricultural fertilizer. A field experiment, the purpose of which is comparing the fertilizing effect of compost with that of biogas residues from source separated household waste, had suggested that application of biogas residue resulted in higher yield and grain quality than compost.

Except for the application in agriculture, biogas residue can also be utilized as potting medium or a substrate for plants in horticulture. But directly application may have negative effects on growth, natural or artificial additives should be added into biogas residues to increase plant productivity in horticulture. Fermentation residues can also be treated to produce compost and liquid fertilizer separately. Here, I would like to introduce “How to make biogas residue quality bio-fertilizer pellets”.

Biogas Residue Fertilizer Making Technology

Biogas residues consists of Biogas dregs and biogas slurry. To make biogas fertilizer, we should separate dregs out first. With the utilization of screw press machine, due to high fibre structure of digestate, it is extruded into dry fiber-based substance.

The digestate is pumped to screw press machine which mechanically separates the digested materials into solids and liquids. The reclaimed liquids are captured and can be reused to manufacture liquid fertilizer. The digested solids are typically used as quality compost. As approximately 85% of the biological activity has been completed in the AD phase, the fiber solids can be applied as bio-fertilizer directly, or granulated into organic fertilizer granules.

Before I introduce you with the granules making technology, I would like to talk about 3 benefits of making biogas dregs into organic fertilizer granules/pellets!

☆ organic fertilizer granules is suitable for commercial use and large scale application

☆ it is easy for transportation and mechanized fertilizing.

☆ granules are much easier for storage, compared with compost.

ps: after liquid-solid separation, if the moisture content is still too high, please add a certain amount of dry grass powder or rice husk to lower the MC to 60%.

Granulating

Granulation has an important effect on the quality of organic fertilizer. It is one of the key processes in the organic fertilizer production line, which is mainly reflected in the nutrient composition uniformity. The biogas residue can be granulated by double roller extrusion granulator. The machine is used for a variety of organic matter fermented granulation, breaking through conventional organic granulation process. It can save a lot of energy and produce spherical particles. Organic matter content can be reach to 100%, which achieves fully organic granulation. The particles can be sieved after granulation, reducing energy consumption. The moisture content of materials is at 20-40% without drying after fermentation.

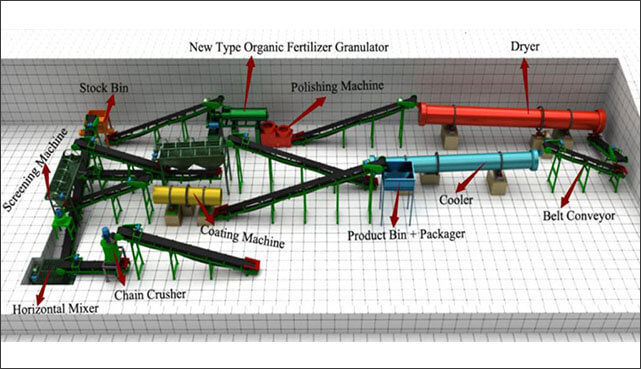

| Screening There are some differences in particle size output from fertilizer granulator, requiring screening. It requires little vibration, low noise. And it is equipped with the cleaning device on the screen surface. It can be fitted with automatic back feeding system, screening unqualified large and small particles of materials. These particles are carried by conveyor and re-crushed to the granulator, helping improve the continuous operation ability of the organic fertilizer production line. |

Drying It is mainly used to remove moisture further in the screened particles so as to meet the requirements of organic fertilizer moisture content. It adopts high-efficiency fertilizer dryer, which can make particles dry and improve the particles shape. |

| Cooling The particles need to be cooled after drying, which helps preserve the particles. The hot particle materials output from fertilizer dryer are sending into the inner counter-current cooler. Dry air, under the action of the cooling fan, are sending into the lower part of the cooler, exchanging heat with humid particles falling from the upper part. After cooling, the temperature difference between the particles and the ambient temperature is less than 5 degrees Celsius. |

Packaging After cooling the particulate material, it is delivered into the warehouse with the help of lifting machine. The materials are packaged by automatic packaging scales, which achieves quantitative weighing and packing. With this, the complete organic fertilizer production process is completed. |

Advantage of Biogas Residue Fertilizer

Full utilization of digestate will help governments meet targets for reducing GHGs along with meeting the requirements of, for example, the EU Nitrates Directive and Water Framework Directive. Compared with untreated manures, using digestate as a biofertiliser has major environmental benefits, such as reduced odours, improved veterinary safety, plant pathogen reduction and the reduction of weed seeds. From the point of view of biogas residue fertilizer, it has lots of advantages.

※Providing nutrients

As organic fertilizer, nutrient content of biogas residue is more than any other retting organic fertilizer. The recovery rate of NPK is up to 90%. The nutrients are quick effective and easily absorbed by crops. There are almost no heavy metal elements.

※Soil improvement

Biogas residue fertilizer is not only with high quality, but also a good soil conditioner. According to the determination, applying biogas organic fertilizer can increase soil 0.17-0.6% of organic matter content, enhance 0.003-0.005% of total nitrogen and improve 0.01-0.03% of total phosphorus. Copper, zinc and iron in soil have different degrees of activation, which makes soil bulk density decreased and increases the total porosity, thereby significantly improving the physical properties of soil. On the other hand, it helps loosen the soil, which is conductive to form soil microbial activity and soil aggregate structure.

※Insect disease prevention

Biogas residue fertilizer contains a variety of biologically active substances, such as amino acid, trace elements, plant growth hormone assassination, B vitamins and certain antibiotics, etc. Ammonia and ammonium salts in biogas residue have a direct role in the killing pests.