A fertilizer plant is always equipped with manufacturing site, production equipment, supporting facilities, technicians, and operating personnel. On one hand, they are the indispensable parts of the complete fertilizer plant; on the other hand, they are very likely to become fire hazard under some circumstances.

Let’s first review two news reports on fire accidents occurred in fertilizer plant in the past few years:

On April 17, 2013, an explosion occurred in a fertilizer plant in Texas, America. Hundreds of people were killed and wounded and about one hundred residential buildings including a retirement home and a school nearby were bombed out.

Cause:

The official said that the explosion may be caused by three factors: arson, the fire on the wire, a broken-down golf cart.

Accident two:

On December 2, 2014, a big fire broke out in a fertilizer plant in Nanning. In the accident, a few tons fertilizer material- chicken feather was burnt out, the plant and equipment were heavily damaged.

Cause: The drying stove was on fire and then the fire ignited the chicken feather and plant nearby. There was no fire-fighting equipment in the plant, so the fire was not put out until the fire-fighters arrived.

As is well-known, fire hazard may exist in any place.

What is the common fire hazard existing in fertilizer plant?

We can analyze the factors one by one.

A. As for the site selection of fertilizer plant, it is the precondition for starting the whole production line in the plant. The safety of the fertilizer plant depends on its location, surrounding environment and other factors. If the fertilizer plant is located in a most likely place for fire accident such as strong lightning activity areas, the fertilizer plant will be in danger. Thus, site selection plays an important role in preventing fire hazard.

B. As for the ventilation condition of the workshop, it may easily produce high temperature and high pressure if the workshop is airtight and airless.

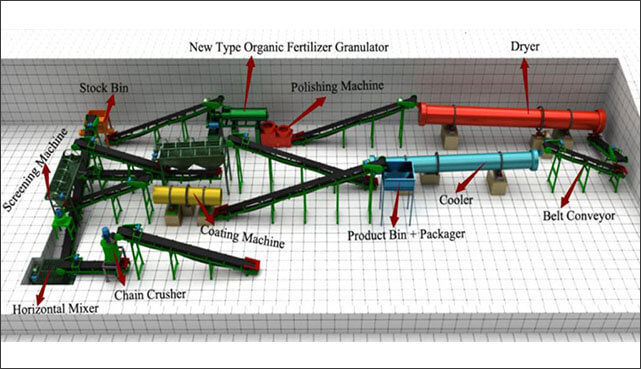

C. As for the production equipment, they are the core components of the fertilizer plant. On one hand, the production equipment for the fertilizer plant are easy to have high temperature and high pressure when they are operated for a long time, especially in the scorching weather. The equipment may be at a risk of fire from overheating if there is no effective monitoring; on the other hand, the cleaning and maintenance of the equipment are very important. If the equipment are not cleaned enough or maintained well, they may be at a risk of fire from overheating because of overlarge resistance and unrepaired components. Besides, it is important to choose high-quality equipment to avoid risk of fire which is possibly due to inferior equipment.

D. As for the facilities, they are also the important parts of the whole plant. The power source, electric wire, lighting, air-condition and other facilities are electric equipment. They may be at a risk of fire from overheating once electric leakage and short circuit happen. Besides, fire fighting devices and source of water are also important in fire prevention. The lack of fire fighting devices and source of water will increase fire hazard.

E. As for the technicians and operating personnel, they are the only most active factors in the fertilizer plant. The fire hazard in other production processes depends on the behaviors and professional quality of the technicians and operating personnel. Any production process may be at the risk of fire if the technicians and operating personnel do not fulfill their duty to monitor and operate the whole plant well. Besides, the lack of safety awareness and safety knowledge of the technicians and operating personnel is also a potential hazard.

F. As for the production process, it runs through the whole plant. In the production process, there must be fire hazard if the fire prevention measure lacks. It may at a risk of fire if the combustible material is mishandled, or the production equipment and facilities are not monitored well. In short, any process of the plant may become fire hazard if there is no corresponding safety measure.

H. As for external factor, it must draw enough attention. Except for the fire hazard in the fertilizer plant, the external factor is also likely to become fire hazard. For example, if the fertilizer plant is lack of safety check, the visitors staying in the fertilizer plant or the external vehicles parking in the manufacturing area bring inflammable or explosives inside, the risk of fire and explosion will increase.

In view of the various factors mentioned above, there are so many fire hazards in the fertilizer plant that we must put forward corresponding preventive measures.

1.The fertilizer plant should be established in a safe zone as far as possible to prevent fire accidents resulted from the external factors such as the bad weather, earthquake and other natural disasters.

2. Manage to monitor and control the temperature of the machines and equipment to prevent high temperature and overheating. When the machines and equipment have high temperature, they should be cooled down in time.

3. Regularly examine and maintain the machines, facilities, fire fighting devices and other equipment to nip fire hazard in the bud.

4. Strengthen safety education and promote the awareness of fire prevention for the personnel in the plant to eliminate fire hazard in mind.

5. Strengthen the supervision of the production process to make sure each process is in away from fire hazard. The supervisors and operating personnel should pay close attention to the process where the fire accident is most likely to occur.

6. In general, a draughty place without sun exposure is necessary to store the materials and production to prevent inflammables or explosives catching fire and exploring.

7. Sometimes, we also need to store the materials and productions according to their nature. The drier materials should be stored away from naked flame. The materials and productions which are most likely to react with each other to produce high temperature or high pressure should be stored separately so as to prevent fire hazard.

8. Strictly check the visitors and external vehicles to prevent inflammables or explosives being brought into the plant to catch fire or explosion.

9. Establish complete safety rules and regulations and strictly enforce the rules and regulations.

10. Fire hazard assessment is also important for preventing fire hazard. It involves every process in the fertilizer production line and all the prevention measures of fire hazard should be taken based on fire hazard assessment.