Worldwide animal manure management has become an urgent problem for poultry farms around the world. Feasibility of large scale pig manure management depends on the local circumstances (local legislation, fertilizer prices) and processing cost. A further economical aspect is to reduce the regular high costs of manure management. The most valuable thing we can do for customers is to reduce the processing cost. Here we make a detailed analysis on methods of turning pig manure into organic fertilizer, and introduce the most suitable compost turner and fertilizer equipment to achieve this objective.

Organic Matters in Pig Manure

At different stages of growth, judging from weight, excretion of pig is varied accordingly. As for a pig whose weight is 60kg, feces amount is approximately 2.3kg per day, urine volume about 3.5kg. pig manure is comprised of 67% -73% water, 18-23% organic matter, 6.54% phosphorus content of dry matter and 3.61% nitrogen content of dry matter. But the content of potassium and magnesium is relatively low, being about 1.5%. 80.1% dry matter manure is organic matter, and easily degradable organic carbon is 27.3%. Hemicellulose and cellulose are lower, fat and lignin are higher. Nutrient, which can be absorbed by the plant in pig manure, is about 70%. Therefore, as organic fertilizer, pig manure has high value of utilization.

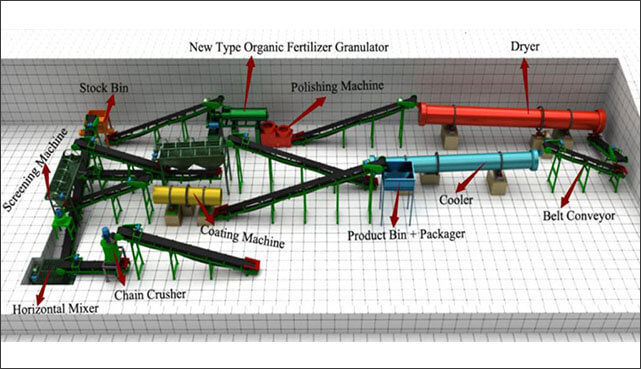

The whole manure fertilizer production process can be divided into 4 parts: pig manure fermentation process-pig manure granulation process-pig manure fertilizer drying process-cooling and screening process

Details of Pig Manure Fermentation Process

1. Locate a spot for the pig manure compost pile

Organic materials, such as sod, grass clippings, leaves, hay, straw, weeds, chopped corncobs, cornstalks, sawdust, shredded newspaper, wood ashes, hedge clippings and many kinds of plant refuse from the garden, should be piled in stripes in level ground: the width of the pig manure compost should be equal to that of the compost turner (hydraulic compost turner being the most suitable one), height of the pile as high as possible, and the length varies in accordance with the fermentation space, being 100m or 50m etc. Turning the pig manure compost pile with hydraulic compost turner every three days at the beginning of the first two weeks, after that turning once a week.

2. Factors affecting pig manure fermentation

The main factors that affect fermentation are temperature, water, C/N and pH.

In the mass production fermentation, it promotes fermentation to create appropriate environment for aerobic microorganisms. The following conditions and technical parameters are supposed to control in the whole pig manure fermentation process. The material moisture is 60-70%. Additives are 5-10%. Fermentation beginning temperature is about 40℃ and high temperature is 60-70℃. Compounds are deposited in the thickness of 30-40cm. As a matter of fact, it is the aerobic fermentation process. Microorganisms are growing in the condition. It also accelerates fermentation. As for fermentation time, ground composting at normal temperatures needs 10-15 days. Moisture of the product is about 20%. It is key phase for pig manure fermentation process.

3. Function of Hydraulic Compost Turner

Our hydraulic compost turner helps to shorten the whole pig manure fermentation time. Organic matters are in continuous aerobic fermentation with the help of the compost turner. Pig manure compost realized an automatic and intelligent control. Pig mature fertilizer is in short fermentation period and low energy consumption. In addition, the quality of product is steady. See more at working principles of hydraulic compost turner.

Pig Manure Granulation Process

New organic fertilizer granulation machine is widely used in organic waste granulation, such as livestock rearing, brewing, sugar manufacturing, paper making and cigarette making etc. This fertilizer granulation machine uses a template aperture to control the particle size. The particles are smooth, round, evenly grained, in high strength and excellent mobility, Particle formation rate is 95%. The machine is characterized by beautiful appearance, simple construction, easy operation, small volume and light weight. This fertilizer granulator is most suitable for companies that produce organic fertilizer.

Pig Manure Drying Process

Although most of the material after granulation has been formed, grains moisture and intensity are substandard. The granules need to be dried after granulating. Rotary dryer is a rotary cylinder that is full of copy board inside. With the action of copy board, the material is fully raised and exchanged with hot air generated by the cowper stove. The temperature of material is increased. The temperature and moisture vapor partial pressure difference would quickly outward diffuse and the water is taken away by the wind, which makes material dry.

Pig Manure Cooling and Screening Process

The drying material is transported to the cooling machines by belt conveyor. Rotary cooler is a rotary cylinder that is full of copy board inside. With the help of lifting board, granulated material is raised and exchanged with the cold air in suction barre. It needs to be cooled down to room temperature, which further improves particle strength and reduces the moisture. After cooling, there exits powdery material. With a screening machine, all the fines and large particles are screened out. With the help of reverting belt machine, fines are mixed with the raw material in the mixer. Large particles are shattered, those particles and fines are sent to blender through the same belt. Thus it forms a complete production cycle, quasi-finished products are entering to the coating process. See more details at: 50,000 tons/year organic fertilizer production line.

Usage of Pig Manure Fertilizer to Plants

1.It is a good choice to use pig manure fertilizer for gardens. It helps store moisture and provides nutrients for plants growth.

2.Many crops need the organic fertilizer. The fertilizer can increase pest and disease resistance of plants.

3.Pig manure can be a good fertilizer for plants. However, due to the risk of pathogens that cause food borne illness in humans, experts do not recommend the use of pig manure to fertilize vegetable gardens

Benefits of Pig Manure Fertilizer to Plants

1.Manure is rich in nitrogen, phosphorus, potassium and organic matter, which is good raw material for organic fertilizer.

2.There is an organism and enzymes in pig mature fertilizer. It can enhance the biological activity and enzymatic activity of land, increase nutrients in soil land improve soil pH value. In this way, it is suitable for plants.

3.Pig mature fertilizer can reduce environmental pollution. It is harmless for human and animals, which is green and environmental friendly fertilizer.

4.Beneficial bacteria generate a large number of metabolites in the process of growth and reproduction, which promotes the conversion and decomposition of organic matter.

It can provide a variety of nutrients and irritating substances for crops directly or indirectly, which is the promotion and regulation for plant growth