What is Screw Extrusion Dehydrator?

Screw extrusion dehydrator is a kind of dewatering machine for processing raw materials of organic fertilizer, suitable for all kinds of animal wastes, municipal sludge, biogas slurry and biogas residues. It is a screw type solid-liquid separator, which adopts continuous screw extrusion technology to separate the pig manure, cow manure and chicken manure into solid and liquid materials. The animal wastes and sludge treated by our screw extrusion dehydrator have low water content, which is only 40%-50%. The separated solid materials can be used directly or processed into organic fertilizer.

The use value of screw extrusion dehydrator is far higher than the cost value. If you have a medium-sized and small farm or biogas plant, this machine is your best option for processing these animal waste materials.

Working Principle of Screw Type Solid-Liquid Separator

Livestock manure is sent to the main machine without blocking by liquid pump. Solid liquid mixture containing large amounts of free water enter into the inner of screw type solid-liquid separator through overflow port. The screw pushes the raw materials to the front of machine gradually, at the same time, the pressure on the leading edge is constantly raised, then the raw material is compressed to the filter screen. In the filter screen, the fibrous solid material is screened out, and become a filter layer for fine particles in free water, so that the free water in the raw materials is squeezed out from the filter screen through filtration and drained through the drainpipe. The solid material is continuously pushed to the outlet and discharged through screw extrusion , meanwhile the filter layer is cleaned.

The whole process is automatic and continuous, saving labor. In order to control the discharging speed and water content, you can adjust the weight block below the host to achieve a appropriate discharge state.

Characteristic of Screw Press Dehydrator

Small volume,reliable operation,long service life. The host is made with ductile iron, the screw shaft, screw blade and the filter screen use stainless steel design.

Wide application scope. This screw press dehydrator is especially suitable for processing various raw materials of organic fertilizer. It can not only process chicken manure, pig manure, cow manure, horse manure, but process high concentration organic waste, such as industrial sludge, vinasse, medical residue, kitchen waste, etc.

Automatic and continuous operation. The machine features with small volume, compact structure, convenient installation and maintenance. It also has the advantages of large capacity, no blockage and low power consumption, is suitable for automatic and continuous operation.

Turing waste into treasure, high use value. Screw press dehydrator is an economic, environmental recovery recycling equipment. It solves the environmental pollution caused by the animal waste, industrial sludge, realizes the recycling of organic waste, and improves the utility value of organic waste. These organic waste including animal waste, industrial sludge can be processed into solid and liquid organic material through screw press dehydrator. The liquid organic material can be drained into a biogas pool, improving the efficiency of anaerobic digestion. The solid organic material can be processed into compound organic fertilizer after granulating.

High dehydration rate. The water content of animal waste can be decreased to 40%. Animal waste after dehydration has low viscosity, no water and odor, is easy to transport.

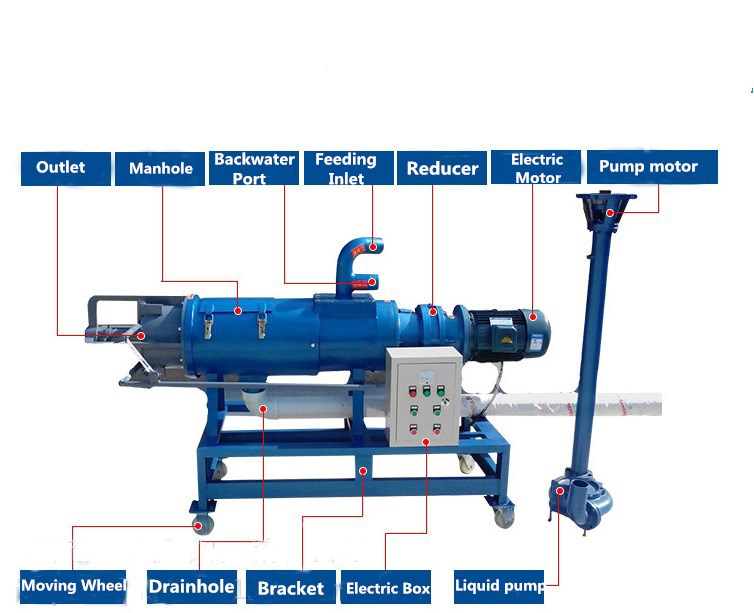

Components of Screw Extrusion Dehydrator

Screw extrusion dehydrator mainly consists of six parts: the host, transfer pump, rubber hose, electric control box, electric motor, reducer. The host includes screw shaft, filter screen, feeding inlet, discharge port.

The humidity of raw materials can be controlled by adjusting the weight block. According to the different raw materials, there are several options available for sieve diameter, such as: 0.25mm, 0.5mm, 0.75mm, 1.0mm.

▼The discharge outlet adopts extended design, so that the pressure of the front of outlet is greatly increased, and the discharge efficiency is improved.

▼The discharge port is held together by bolts, effectively preventing the falling off problem caused by excessive pressure during operation.

▼The transfer pump adopts non-clogging design to prevent blockages, enhancing dehydration efficiency.

▼The screw extrusion dehydrator adopts removable roller device, easy to move. It is also possible to remove the rollers to ensure the stability of machine during operation.

▼The oil filler neck features with the convenience of design, easy to change aeration and add lubricant.

▼The manhole uses humanized snap-fit design, reliable fixation, convenient to open and clean.

▼The electric control box is equipped with dial indicator that can show the operation condition of machine more intuitively. The inside has over-current protection to ensure safe operation.