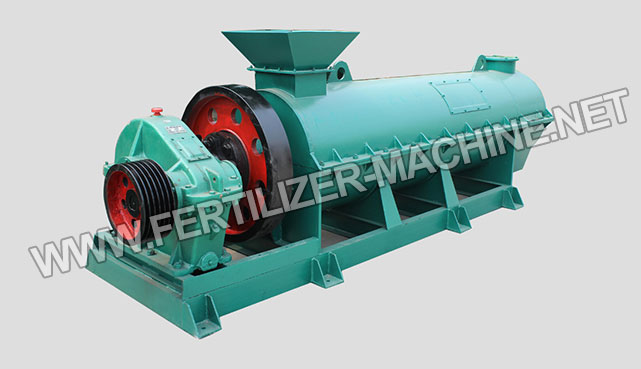

Double Roller Fertilizer Granulator Introduction

Double roller extrusion granulator is suitable for producing high, medium and low concentrations of compound fertilizer. The granules it makes are of oblate shape. Roller fertilizer granulator adopts no drying normal temperature technology, having low investment, fast returns and good economic benefit. Integrating granulation, forming and screening, roller granulator has the features of nice appearance, easy operation, and low energy consumption.

Advantages of Roller Fertilizer Making Machine

1.No drying process, normal temperature granulating, one-step forming.

2. Saving energy and cost, no waste water or gas emission.

3. Compact structure, easy and stable operation, easy maintenance.

4. Press rollers adopt new metal which is resistant to corrosion, wear and impact.

5. The press rollers can be designed to make different shapes and sizes of materials.

Wide Application of Double Roller Granulator Machine

1. Wide adaptability, suitable for compound fertilizer, medicine, chemical industry, feed, coal, and metallurgy, etc. High granulation rate.

2. The granulator can produce compound fertilizer of various concentrations and types, including organic fertilizer, inorganic fertilizer, biological fertilizer and magnetic fertilizer.

3. The production of rare earth, ammonium carbonate and ammonium sulfate compound fertilizer takes the lead throughout our country.

Working Principle of Double Roller Extrusion Granulator

The motor drives triangle belt, belt pulley, and speed reducer, making the granulator machine works. The mixed materials are fed from the feeding hopper, pass through the counter-rotating rollers, and are extruded into slices under the strong extrusion force. Through the driving chain, the power is transferred from the press roller to the crushing roller. The slices flow downward to the crushing chamber, where the slices are crushed by the counter-rotating crushing rollers and screened to get the required granular fertilizer. The granular fertilizer are discharged fro the outlet, while powdery materials are returned to be extruded.

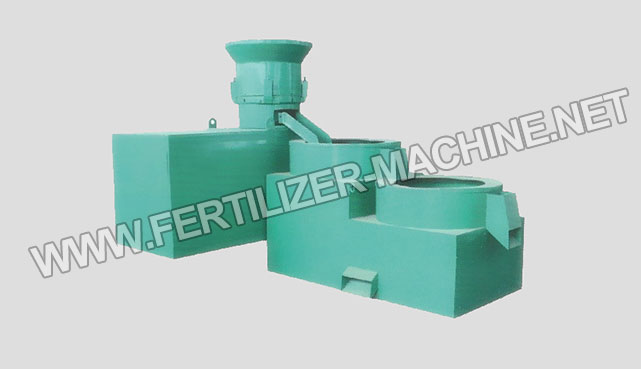

ALCDZJ-II Type Dual Shaft Granulator

DZJ-II type dual shaft granulator adopts dual input transmission, which improves the input power ratio, and meanwhile ensures the lubrication and sealing performance of transmission gear. Bearing bracket adopts high quality anti-corrosion cast materials, making it more stable, and greatly improving the service life of rolling bearing.

Working Video of Double Roller Extrusion Granulation Machine:

Technical Data of Double Roller Extrusion Granulation Machine

|

Model

|

ALCDZJ-I 1.0

|

ALCDZJ-I 2.0

|

ALCDZJ-I 3.0

|

ALCDZJ-I 4.0

|

ALCDZJ-II 1.0

|

ALCDZJ-II 2.0

|

|

Output(t/h)

|

1-1.5

|

1.5-2.5

|

2.5-3.5

|

3.5-4.5

|

1-2

|

1.5-2.5

|

|

Power(kw)

|

15

|

18.5

|

30

|

45

|

15

|

18.5

|

|

Press roller size(mm)

|

Φ150*220

|

Φ150*300

|

Φ186*300

|

Φ300*300

|

Φ150*220

|

Φ150*300

|

|

Feed size(mm)

|

≤0.5

|

≤0.5

|

≤0.5

|

≤0.5

|

≤0.5

|

≤0.5

|

|

Finished product size(mm)

|

Φ2.5-Φ10

|

Φ2.5-Φ10

|

Φ2.5-Φ20

|

Φ2.5-Φ30

|

Φ2.5-Φ10

|

Φ2.5-Φ20

|

|

Material moisture content(%)

|

2-5

|

2-5

|

2-5

|

2-5

|

2-5

|

2-5

|