Organic Fertilizer Granule Polishing Machine Introduction:

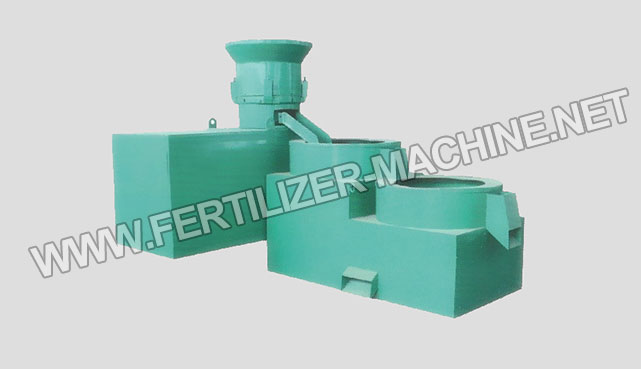

Based on the structure of Flat Die Extrusion Granulator, the Organic Fertilizer Granule Polishing Machine is used to process fertilizer granules. It can make the cylindrical particles into spherical particles at one time. The granulation rate can reach as high as 98%, no returning materials created.

With high production rate and strong flexibility, the Organic Fertilizer Granule Polishing Machine avoids the disadvantages of the traditional fertilizer production equipment. Thus, it is considered as your best choice to produce spherical organic fertilizer granules in a more effective and energy-saving way.

Organic Fertilizer Granule Polishing Machine Features:

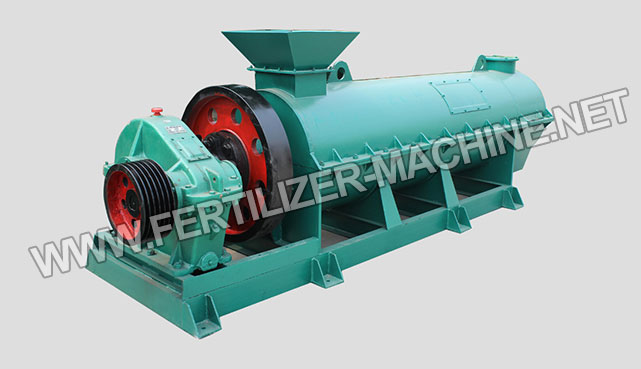

1. This machine is featured with perfect appearance, simple structure, easy operation and maintenance, reliable quality, small volume and light weight.

2. Organic fertilizer polishing machine can be combined with other machines flexibly, the number of the polishing machine can be changed according to customers’ requirements.

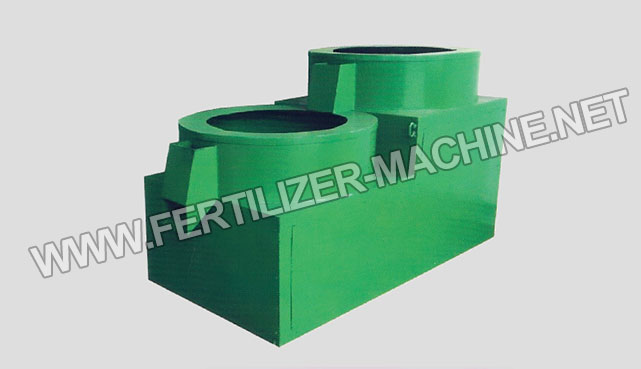

3. It is made of two or more than two gradated polishing drums, in which the particles will be polished for many times. After that, the particles will be expelled from the discharge gate. The final particles are uniformly shaped and highly concentrated.

4. This machine can be manufactured with strong flexibility, which solves the disadvantages of the traditional equipment for organic

fertilizer granule production.

5. The polishing machine can beautify the appearance of the organic fertilizer granules, which will greatly improve the levels as well as the images of the products. Thus, it can help the products enjoy more popularity in the competitive market.

6. This machine has a great excess capability, so no material limitation equipment is needed even if it works under the condition of full load.

7. It has the additional function of drying materials, so it has fewer requirements for the moisture of the raw materials, which effectively reduce the expenses for drying process.

8. This machine works under low temperature and pressure, so the activity of the organic fertilizer will not be affected.

9. It is widely used for polishing all kinds of organic fertilizer granules, of which the quality can be ensured.

Organic Fertilizer Granule Polishing Machine Working Principles:

The cylindrical particles made by the Flat Die Granulator will be transformed into the Polishing Machine before they are hardened. Under the influences of the centrifugal forces, the cylindrical particles will be turned into the spherical ones rapidly. With the additional function of drying, it can help leave out the organic fertilizer drying process, which will reduce the production expenses and provide a

more efficient and economic way for customers.

Organic Fertilizer Granule Polishing Machine Applications:

It is mainly used for polishing organic fertilizer. And the raw materials for organic fertilizer production can be diverse.

1.Agricultural Waste: straws, mushroom residues, bio-gas residues etc.

2.Industrial Waste: vinegar residues, sugar residues, lees etc.

3.Animal Manure: chicken manure, cow manure, horse manure etc.

4.Household Garbage: kitchen waste, food waste, restaurant garbage etc.

5.City Sludge: drainage sludge, river sludge etc.

Technical Data of Organic Fertilizer Granule Polishing Machine

| Model | ALCPYS800 | ALCPYS1000 | ALCPYS1200 |

| Output(t/h) | 1 | 2 | 3 |

| Equipped Power(kw) | 11 | 11 | 15 |

| Disc Diameter(mm) | 88 | 1000 | 1200 |

| Overall Dimensions(mm) | 2800x920x1290 | 3100x1020x1390 | 3400x1120x1490 |