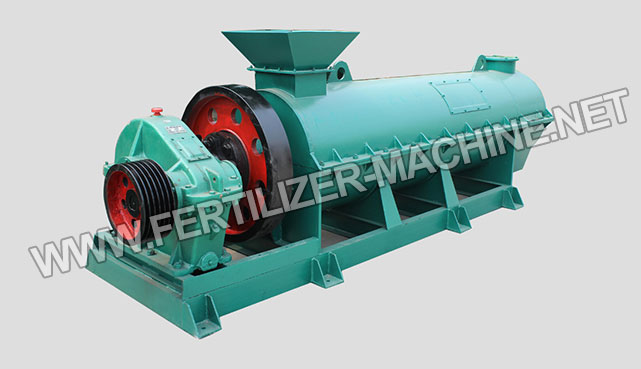

High Output Rotary Drum Granulator Introduction:

The rotary drum granulator manufactured by us is used to make raw materials into granules in the specified shapes.

The high-efficiency fertilizer granulating machine is considered as the most important equipment in large-scale compound fertilizer production.

By adding a certain number of steams and vapors, raw materials in the rotary drum will become uniformly humid during the granulation process. Then a series of chemical reactions will occur. In this machine, the fertilizer particles squeeze each other and roll into fertilizer particles. The uniformly formed fertilizer particles are of 3-4mm. With the continuous adding of raw materials and rotating of the drum, a large-scale production as well as the working efficiency will be insured.

Features of the Rotary Drum Granulator:

2. Heat the raw materials by adding steams and vapors. Reduce the moisture of the granulated raw materials and therefore improve the efficiency of the drying process.

3. The linings are made of rubber engineering plastics, which can efficiently get rid of the adhesion between the raw materials and the inside wall of the rotary drum.

4. Being made of anti-corrosive materials. Thus, it has a long service life.

5. Large production, low energy consumption and easy maintenance.

6. Visible working process. Workers can solve the problems during granulating process in time.

Rotary Drum Fertilizer Making Machine Structures:

1. Bracket Part

Most weight of the machine is supported by the bracket part. So this part is made of medium carbon steel sheets and channel-section steels to meet its high compressive capacity. Additionally, the tug fixed with the bracket is also of great significance. Considering the frictions between the tug and the belt, the tug is made of the anti-corrosive and wear-resistant materials to ensure its long service life.

2. Conveyors Part

Conveys are the indispensable parts in the whole production process. They connect different parts of the machine and make the granulation process more efficient. This part is made of high-quality channel-section steels, which meet the strict quality requirements. The main engine and the deceleration machine fixed with the conveyors are made of ISO certificated materials, which ensures the quality of this part.

3. Big Gear Wheels

Big gear wheels are fixed with the body of the machine. They run relatively to the small gear wheels, with which they work together to make the machine run smoothly. This part is made of high-tech wear-resistant materials, which prolong a longer service life.

5. Body of the Machine

It is the central part of the machine and made of the superior medium carbon steel sheets. The special linings made of rubber engineering plastics which are anti-corrosive and wear-resistant ensure the high quality of the machine.

Rotary Drum Fertilizer Pellet Machine Applications:

It is used for fertilizer granulation, especially in large-scale compound fertilizer production line. Because the particles are uniformly formed, it will ensure the final quality of the fertilizer granulation production. Additionally, it can be used for different kinds of granulation, including the cold and hot granulation, low, medium and high concentrations of compound fertilizer production.

Technical Data of Rotary Drum Fertilizer Making Machine

| Model | ALCZG1.2×4 | ALCZG1.4×5 | ALCZG1.6×6 | ALCZG1.8×7 | ALCZG2.0x8 | ALCZG2.2×8 |

| Inclination(0) | 2–2.5 | 2–2.5 | 2–2.5 | 2–2.5 | 2–2.5 | 2–2.5 |

| Barrel Internal diameter(m) |

1.2 |

1.4 |

1.6 |

1.8 |

2.0 |

2.2 |

| Barrel Length(m) |

4 |

5 |

6 |

7 |

8 |

8 |

| Barrel Rotation Speed(r/min) |

17 |

14 |

11.5 |

11.5 |

11 |

10.5 |

| Power(kw) | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 |

| Prod Capacity(t/h) |

1-3 | 3-5 | 5-8 | 8-10 | 10-15 | 15-20 |

| Overall dimensionsL x W x H(m) |

4.6×2.2×2.0 | 4.8×2.8×2.3 | 7.0×3.2×3.1 | 8.3×3.5×3.3 | 9.1×3.6×3.5 | 9.5×4.4×3.9 |

| Weight(t) | 2.7 | 8.5 | 12.0 | 18.5 | 22.0 | 28.0 |