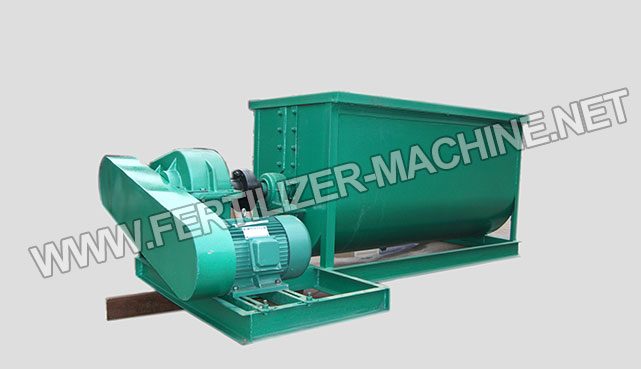

Introduction of Horizontal Fertilizer Mixer

The raw materials for fertilizer granulation should be mixed evenly after batching according to the formula, so raw material blending equipment is an essential component in the production of fertilizer. We manufacture both single shaft horizontal fertilizer mixing machine and double shaft blender.

With features of high mixing uniformity, low material residue, the fertilizer horizontal mixer is widely used for mixing the raw materials in both organic fertilizer and compound fertilizer production, especially double-shaft horizontal mixer, with its larger capacity, is deeply loved by our clients. Double-shaft horizontal mixer is mainly used to humidify and mix powdery materials in the fertilizer industry. The machine uses two relative rotative shafts with spiral blades mounted to mix the materials. As the spiral blades have multiple angles, raw materials can be mixed quickly and effectively, regardless of their shape, size and density. The blender is also suitable for mixing viscous material with 30% moisture content. Perfect quality and excellent after-sales service has won high praise and favorably commented from customers.

Features of Double-shaft Horizontal Organic & Compound Fertilizer Mixer

1. New rotor design. Minimum clearance between rotor and the mixer body can be adjusted approaching zero, which reduces residual value of raw materials. Materials are mixed evenly in the blender, with the improving of mixing uniformity.

2. Materials with larger size can also be crushed during mixing.

3. More reasonable body design, excellent in shape, and easy-operation and maintenance.

4. Fast mixing speed, good mixing uniformity, fast discharging speed, low material residual.

5. Adopt stainless steel spiral blade with hard steel tool bit, good wear-resisting performance, long service life.

How does Double-shaft Horizontal Fertilizer Blender Work?

The horizontal mixer is composed of frame, transmission part and mixing part. While the quantified powdery material flows into the mixing tank through feed opening, water with certain pressure are atomized and sprayed on the raw material. The motor drives the speed reducer and makes the main shaft rotate. The spiral blades, which are welded on the shaft rotate synchronously, mix the materials in the tank evenly, forming loose balls with uniform moisture content. After the materials are fully mixed, open the discharge port under the tank and the materials will be discharged from the blending equipment, and conveyed to the fertilizer granulation.

Techinical Data of Horizontal Fertilizer Mixer

|

Model

|

Shaft Speed

(Y/mm) |

Rotating Diameter

(mm) |

Output

(t/h) |

Weight

(kg) |

Speed Reducer

ALC-JZQ |

Electric Motor

|

|

ALCZYQ-QZ 400

|

52

|

400

|

20

|

2350

|

400-1v-2

|

Y160M-4-11

|

|

ALCZYQ-QZ 450

|

52

|

450

|

25

|

2620

|

500-1v-2

|

Y160L-4-15

|

|

ALCZYQ-QZ 500

|

53

|

500

|

30

|

2980

|

500-1v-2

|

Y180M-4-18.5

|

|

ALCZYQ-QZ 550

|

53

|

550

|

35

|

3450

|

650-1v-2

|

Y180L-4-22

|

|

ALCZYQ-QZ 600

|

52

|

600

|

40

|

3850

|

650-1v-2

|

Y200L1-4-30

|

|

ALCZYQ-QZ 650

|

52

|

650

|

45

|

4260

|

750-1v-2

|

Y225S-4-37

|