Introduction of Organic Fertilizer Production Plant

The fertilizer production line manufactured by us can produce 30,000 tons of organic fertilizer granules per year, with tons of various organic wastes being turned into organic fertilizer. The bio-organic fertilizer plant not only turn waste (such as chicken manure, kitchen waste etc.) into treasure, but also reduce environment pollution. The granular shape can be cylindrical or spherical, convenient for transportation and application. The equipment is optional according to your actual requirement.

The organic fertilizer plant has rich raw material resources. The equipment may differ for different materials.

1.Animal waste, animal manure, such as chicken, pig, cattle, sheep, horse, rabbit, animal residue, such as fish meal, bone meal, feather, fur, silkworm excrement, biogas residue, etc.

2.Agricultural wastes. Crop straw, vine, soybean mean, rapeseed meal, cottonseed meal, caster bean meal, tea seed meal, yeast powder, mushroom residue, etc.

3.Industrial waste. Vinasse, vinegar residue, manioc waste, filter mud, herb residue, furfural residue, etc.

4.Municipal sludge. River sludge, pound sludge, ditch sludge, sea mud, lake mud, sewage sludge, humic acid, turf, lignite, danty, fly, ash, etc.

6.Extracted or concentrated organics, seaweed extract, fish extract, etc.

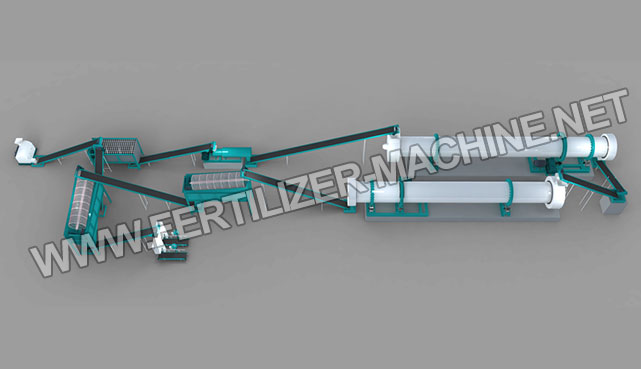

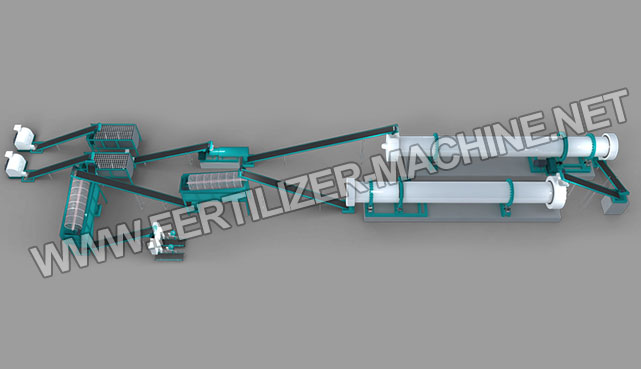

Main Equipment in 30,000 Ton Organic Fertilizer Granulator Line

1. Compost Turner

Fermentation process decomposes the organic waste and turns them into organic fertilizer. We provide 4 types of compost turners: self-propelled organic fertilizer compost turning machine, hydraulic compost turner, groove type fertilizer compost turner, and groove type hydraulic compost turner, all of which have gained great popularity in the international market. Our clients can choose whichever they like according to their preference.

2. Semi-wet Material Crusher

The fermented materials enter into the semi-wet material crusher, which can crush fermented materials with moisture content within 30%. The size can reach 20-30 mesh, meeting the requirement of granulation.

3. Horizontal Mixer

After crushing, auxiliary materials are added into the materials according to the formula and mixed in the mixer. We provide single-shaft mixer and double-shaft mixer for you to mix the materials evenly.

4.New Type Organic Fertilizer Dedicated Granulator

This machine can help reduce the energy that is wasted in the drying process, because granules can be immediately screened after the granulation process. The purity of the organic fertilizer granules can reach as high as 100%, which makes the pure organic fertilizer production come true and meet the needs of the customers directly. The quality of the fertilizer granules can be ensured at the same time. So this machine is featured with low energy consumption, low production expenses and high production quantity and is considered as your best choice for pure organic fertilizer production.

5. Rotary Screening Machine

Granules from the granulation system are screened by the rotary screening machine. The machine adopts combined screen, which is convenient for maintenance and replacement. After screening, unqualified granules are returned to the crusher.

6. Rotary Drum Dryer

The granules coming from the granulator have high moisture content and should be dried to meet the standard. Rotary drum dryer adopts hot air to dry the pellet, high thermal energy efficiency, uniform drying.

7. Rotary Drum Cooling Machine

Dried fertilizer has high temperature and should be cooled to prevent caking. Rotary drum cooling machine is used in combination with the dryer to further remove the moisture and lower the temperature of fertilizer. High cooling efficiency, strong adaptability.

8. Rotary Screening Machine

Cooled fertilizer granules enter into the rotary screening machine. Unqualified granules are returned to the crusher. Qualified granules are sent to the packing system.

9. Granules Packing Machine

Granules packing machine is used for the quantitative packing of fertilizer granules. It consists of automatic weighing and packing machine, conveyor, sealing machine and feeder. High weighing accuracy, convenient operation. Packed fertilizer will be stored for sale

Features of Organic Fertilizer Granulation Production Line

1. Adopt semi-wet material crusher, having strong adaptability to the moisture content.

2. Granule polishing machine makes spherical granules with uniform size, smooth surface and high strength. Suitable for connecting with various granulator.

3. Belt conveyor and other supporting equipment are used to connect the whole line.

4. Compact structure, stable performance, easy operation and maintenance.

5. The equipment is optional according to your actual requirement.

Technical Data of 30,000 T/Y Organic Fertilizer Production Line

|

Product Item

|

Model

|

Motor Power

(kw) |

Prod Capacity

(t/h) |

Weight

(t) |

Inclination

|

Dimension

L x W x H(mm)

|

|

Fertilizer Mixer

|

ALCZYQ-QZ 400

|

20

|

2.3

|

|||

|

New Type Fertilizer Granulator

|

ALCYSL-120

|

75

|

6-8

|

|||

|

Rotary Drum Dryer

|

ALCZG18150

|

18.5

|

7-10

|

2-5

|

Shell L x inner dia:

15000*1800 |

|

|

Rotary Drum Cooler

|

ALCLQ18160

|

18.5

|

2-5

|

Shell L x inner dia:

16000*1800 |

||

|

Rotary Drum Screening Machine

|

ALCGS1.5×5.0

|

5.5

|

5-10

|

3.8

|

2-2.5

|

Shell L x dia:

5000*1500 |

|

Rotary Drum Coating Machine

|

ALCBM1200×4000

|

5.5

|

~5

|

3

|

Shell L x inner dia:

4000*1200 |

|

|

Semi-wet Material Crusher

|

ALCBSFS-90

|

37

|

4-8

|

2120*2040*1800

|