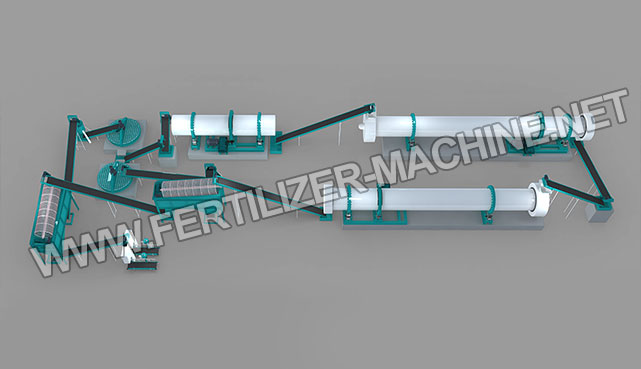

Introduction of Compound Fertilizer Production Line

Compound Fertilizer is the fertilizer which contains two or three nutrients of N, P; K. Compound fertilizer is available in powder or granular form. It is usually used as topdressing and can also be used as base manure and seed manure. The whole compound fertilizer production line manufactured by us includes: belt weigher, disc mixer, rotary drum granulator, rotary drum dryer,rotary drum cooler, rotary drum coating machine, chain crusher, rotary screening machine, automatic packaging machine, belt conveyor and other accessories.

This fertilizer production line is mainly used to granulate compound fertilizer granules using materials of NPK, GSSP, SSP, granulated potassium sulphate, sulphuric acid, ammonium nitrate, and others. The compound fertilizer equipment has advantages of running stable, low malfunction rate, small maintenance and low price.

According to the capacity, the compound fertilizer production line is divided into 20,000 tons, 30,000 tons, and 50,000 tons. With many years experience of manufacturing compound fertilizer equipment, we can also assemble fertilizer production line with larger output in the light of customers’ demands.

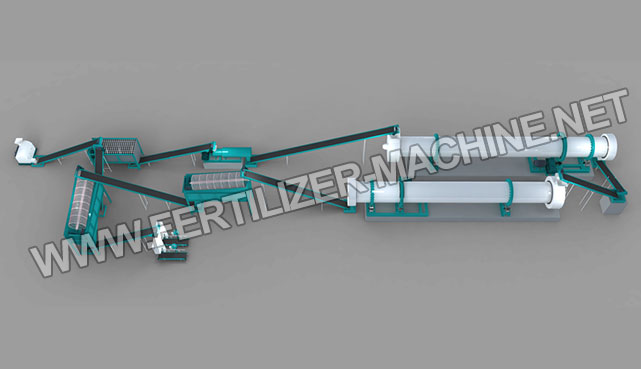

Main Components of 50,000 ton Compound Fertilizer Production Line

1.Material ingredient: Urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, TSP, SSP), potassium chloride (potassium) and other raw materials are dispensed according to a given proportion (according to the market demand and the soil test results). N, P, K, additives, and trace elements are introduced into proportioner through the belt weigher in fixed proportion. According to formula ratio, all raw materials flow to the belt uniformly, which can be called Premix. It ensures accurate formula, and achieves an efficiently continuous processing.

2. Raw materials mixing: transforming proportionate raw materials to disc mixer which is used to evenly mix all materials to improve the uniformity content of fertilizing ingredient.

3. Granulating: well-mixed raw materials are transformed to rotary drum granulator for pelletizing. The reason we choose rotary granulator is that rotary drum granulator is with a rather large-output of fertilizer granules. It is suitable for large-scale compound fertilizer production. It is an essential and indispensable part in the whole line.

4. Fertilizer drying: compound fertilizers need to be dried to a certain moisture content after pelletizing to increase the physical character. After being dried, the fertilizer are easier to storage.

5. Fertilizer cooling: temperature of fertilizer pellets after drying is too high, very easy to agglomerate. after cooling, the fertilizer granules are easier for bagging, preserving, and transporting.

6. Fertilizer grading: we use rotary screening machine to screen the end products. All fines and large particles can be screened out using our rotary drum screening machine. Then, fines being transported by belt conveyor are back to horizontal mixer for remixing and re-granulating with raw materials. While large particles needs to be crushed in chain crusher before re-granulation. Quasi-finished products are conveyed into compound fertilizer coating machine. In this way, a complete production cycle is

formed.

7. Fertilizer coating: The qualified products are coated in this process to increase the brightness and roundness.

8. Fertilizer packaging: our automatic fertilizer packager is specially designed and manufactured for end products bagging. Independent suspension sensor makes sure that signals can be relayed stationary and effectively, and also improves weighting precision. As feeding speed is controlled by controller, customers can can set the speed at random.

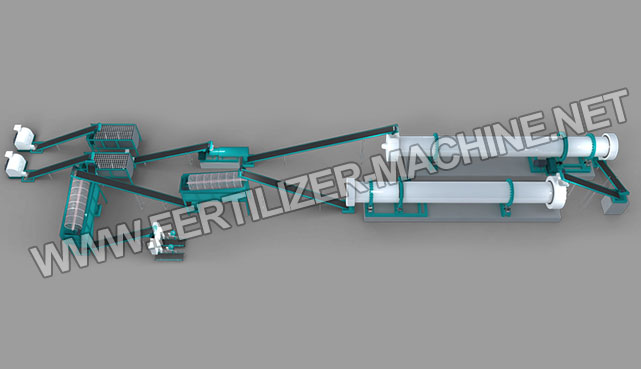

Features of 50,000 ton Compound Fertilizer Production Line:

1. The complete set of equipment process layout is designed compactly, scientific with advanced technology, stable operation, easy maintenance, low energy consumption and good economic returns.

2. Wide adaptability of raw materials, suitable for the granulation of compound fertilizers, pharmaceuticals, chemicals, feed and other raw materials and products into the grain rate.

3. The process technology of N-P-K fertilizers is advanced and reliable. According to the compatibility and crossability of the three raw materials, N-P-K compound fertilizer in different percentage composition can be manufactured by process of dissolving, mixing, pelleting, drying and screening, applicable for different requirements of soils and crops.

4. Compound fertilizer production line equipment use high-quality anti-corrosion, wear-resistant materials, good-looking appearance, long life, high granulation rate, and wide range.

1. Sulfur coated urea production process

2. Monosodium glutamate wastewater organic and inorganic fertilizers process

3. Sugar molasses waste organic and inorganic fertilizer process

4. Urea-based fertilizer spray granulation process

5. Acid compound fertilizer granulation process

6. Fertilizer tower granulation process

7. Powdery industrial waste inorganic fertilizer process

8. Large particle urea production process

9. Seedling Substrate fertilizer production process

Working Video of Rotary Drum Compound Fertilizer Granulation Line

Technical Data of 50,000 Tons/Year Compound Fertilizer Production Line

|

Product Item

|

Model

|

Motor Power

(kw) |

Prod Capacity

(t/h) |

Weight

(t) |

Inclination

|

Dimension

L x W x H(mm)

|

|

Disc Mixer

|

ALCPJ2200

|

11

|

6-10

|

16.68

|

2300*2216*1503

|

|

|

Rotary Drum Granulator

|

ALCZG1.8×7

|

15

|

8-10

|

18.5

|

2–2.5

|

830*350*330

|

|

Rotary Drum Dryer

|

ALCZG20200

|

22

|

8-14

|

2-5

|

Shell L x inner dia:

20000*2000 |

|

|

Rotary Drum Cooler

|

ALCLQ18160

|

18.5

|

2-5

|

Shell L x inner dia:

16000*1800 |

||

|

Rotary Drum Screening Machine

|

ALCGS1.5×5.0

|

5.5

|

5-10

|

3.8

|

2-2.5

|

Shell L x dia:

5000*1500 |

|

Rotary Drum Coating Machine

|

ALCBM1400×4000

|

7.5

|

~7

|

3

|

Shell L x inner dia:

6000*1600 |

|

|

Chain Crusher

|

ALCLP800

|

15

|