Where there are animals, there is animal manure. With the intensification, industrialization and specialization of the cattle industry, environment pollution and cow dung comprehensive utilization issues in cattle farm have become increasingly obvious. One animal unit of fattened cattle produces an average of 10.59 tons per year and dairy cows 15.24 tons per year.One dairy cattle farm, with 2,500 cows produces as much waste as a city with around 411,000 people. For example, if there are 14 million dairy herds, daily excretion of cow manure drops up to 20-30 million tons. Due to lack of effective means of cow manure treatment, especially in large-scale dairy farms, cow manure packing pollution has been serious concern. In some places, pollution of cow dung is over total amount of industrial pollution and some pollution is up to twice than industrial pollution. Manure management is the big problem in cattle farms.

Cattle herds (million):

|

India

|

Brazil

|

China

|

America

|

Pakistan

|

Australia

|

New Zealand

|

|

323.74

|

210

|

198

|

79.22

|

29.8

|

26.3

|

4.39

|

In fact, cow dung itself is a good source of organic fertilizer. Cattle manure is basically made up of digested grass and grain. Cow dung is high in organic materials and rich in nutrients. It contains about 3 percent Nitrogen, 2 percent Phosphorus, and 1 percent Potassium (3-2-1 NPK). Except for a lot of organic matter, N, P, K and other essential plant nutrients, cow dung contains a variety of enzymes and microorganisms. After making into organic fertilizer, cow dung organic fertilizer can play an irreplaceable role in soil, which helps to improve soil fertility, organic matter, soil physical and chemical property and microbial environment.

Though cow manure is an excellent fertilizer, fresh dung has a disagreeable odor, high ammonia levels that may burn plants, and may contain excess salt. Composting will create good fertilizer or topdressing without the odor, salt concentration or toxic ammonia levels found in fresh dung.If farmers apply cow manure to soil without fully decomposition, it will increase oxygen consumption. Under high temperature, crops root system is burning and it produces harmful substances like pathogens. It not only cannot achieve the desired stimulation effect, but leads to secondary pollution to soil, water, air and food.

Though cow manure is an excellent fertilizer, fresh dung has a disagreeable odor, high ammonia levels that may burn plants, and may contain excess salt. Composting will create good fertilizer or topdressing without the odor, salt concentration or toxic ammonia levels found in fresh dung.If farmers apply cow manure to soil without fully decomposition, it will increase oxygen consumption. Under high temperature, crops root system is burning and it produces harmful substances like pathogens. It not only cannot achieve the desired stimulation effect, but leads to secondary pollution to soil, water, air and food.Therefore, cow manure can only beused after compost maturity and harmless treatment. After the cow dung compost, it can be further processed into organic fertilizer in form of powder and granules. Organic fertilizer manufacturers can add chemical fertilizer to produce organic and inorganic fertilizer, achieving commercial organic fertilizer production.

Fresh cow dung nutrient content

|

Organic matters

|

Nitrogen

|

Phosphorus

|

Potassium

|

pH

|

Moisture content

|

C/N

|

|

14.5%

|

0.30-0.45%

|

0.15-0.25%

|

0.10-0.15%

|

6.0-7.5

|

80-90%

|

19:1

|

Solid cow dung manure nutrition content

|

Organic matters

|

Nitrogen

|

Phosphorus

|

Potassium

|

Calcium

|

Moisture content

|

|

20%

|

0.32%

|

0.14%

|

0.30%

|

0.40%

|

77%

|

Cow Dung Compost and Organic Fertilizer Production Technology

High-grade organic fertilizer production relies on advanced production technology. Combined with years of experience in design and project construction practice, this article presents the following cow dung organic fertilizer production techniques. It includes two major procedures: raw materials aerobic composting process, and commercial organic fertilizer granulation process.

The First Step: Composting

Organic fertilizer raw materials aerobic composting technology

Traditional composting is a natural way to compost without fertilizer making machine. In the meanwhile, it has disadvantages over large area, slow composting, poor quality, low efficiency, high labor intensity and harsh surroundings. Under aerobic conditions, modern aerobic composting technology uses aerobic microorganisms with compost windrow turners to realize stabilization and detoxification. Comparatively speaking, aerobic composting has features of simple process, low investment and low operating cost, which can kill pathogens. It is a safe, effective and reasonable way to deal with cow manure.

Before composting, cow dung should be pretreated in order to meet conditions of water and C/N. In general, the fresh cow manure carbon-nitrogen ratio is 19-23: 1, which basically meets the standards of compost. However, water condition varies considerably. Water content of cow dung in large-scale farms is up to 60-80%.It needs to drop to 50-60% before compost. Mixing reused materials is recommended to use while reducing moisture, namely, add fermented cow manure with low moisture (30% water content) to cow dung with high moisture. After mixing two kinds of materials, it can efficiently decrease the total moisture of compost. The advantages of this treatment is wide materials resource and low treatment cost. If fresh cow dung water is up to 80%, reducing the moisture can also use solid-liquid separation method.

Notice: heavy manures, like that of cows, should be mixed with lighter materials, such as straw or hay, in addition to the usual organic substances from vegetable matter, garden debris, etc.

Working video of cow dung dewatering machine-Solid liquid separation method/technology:

Here we introducing 2 advanced composting methods for aerobic compost of cow dung

(1) Windrow composting process

(2) Aerobic composting fermentation with solar energy

According dung raw water content, you can choose one of these composting processes or use two ways to compost cow manure together. For example, you can compost cow dung by way of groove type composting. And then remove the harmless material to windrow composting area from the fermentation tank. The materials take place secondary fermentation and aging to further reduce the moisture, prompting organic nutrients huminification and mineralization. At last, cow manure can be well-composted. When you use two kinds of technology simultaneously, the investment in fertilizer machinery may be increased slightly. However, the composting efficiency and quality is improved.

How to tell whether the cattle manure is fully fermented or not?

Firstly, look at the color. When the color of cow manure is brown or dark brown, it shows that ammonium nitrogen content increases significantly. Secondly, look at the leach solution. Add clear water (1:5) to thoroughly decomposed organic fertilizer. Wait for 5 minutes to look lixivium color. Thirdly, look at the volume.The volume of well-composed organic fertilizer is sunk 1/3 ~ 1/2 than just piled windrow. Finally, spread out decomposed organic fertilizer in the field.The thickness of compost is not more than 20 cm, and it should be mixed and turned regularly to reduce water content to less than 50-60%.

The Second Step: Granulation

Why should we further process cow dung compost into powder/granular fertilizers?

Decomposed cow dung realizes harmlessness and stabilization treatment, which meets the criteria of efficient utilization as organic fertilizer. Nonetheless, it has not yet reached the degree of commercialization for sale, leading to some limitations of apply effect and use range.Due to the low overall nutrient in compost, it only plays as a part of the base fertilizer. There are differences with the existing agronomic practices and crop fertilizer-requiring features. Therefore, it is necessary to further make compost to powdery or granular organic fertilizer and organic and inorganic fertilizer through the subsequent composting process.Based on double nature of organic fertilizer and inorganic fertilizer, organic and inorganic fertilizer has characteristics of long fertilizer efficiency, activating inorganic nutrients in the soil, high nutrient and fast fertilizer efficiency.In this way, it achieves the advantage compensation and quick and long-acting fertilizer efficiency. Thus, organic and inorganic fertilizer can be as a leading product while planning and designing organic fertilizer plant, taking into account the production of organic fertilizer products.

It depends on market demands to make cow dung compost into granules or powder. In order to keep balanced nutrient and easy transportation, you can make organic and inorganic fertilizer into granular products.The particle is shaped of cylinder and sphericity. Finished particle moisture content requirements are as followings, which is organic fertilizer ≤20% and organic and inorganic fertilizer ≤10%.

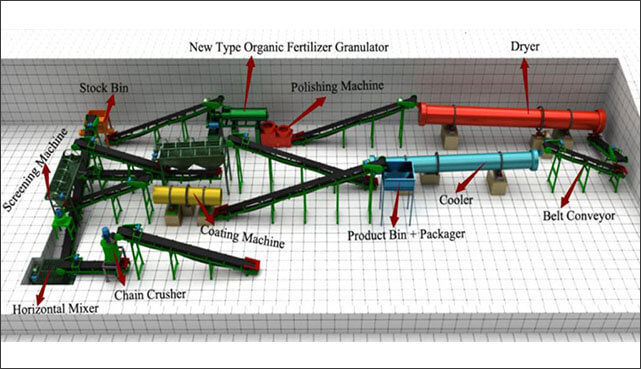

Commercial organic fertilizer production process includes crushing, batching, mixing, granulating, drying, cooling, screening and packaging, etc. It is appropriate that production capacity is 1 ton to 10 tons per hour of single cow dung organic fertilizer production line. Small production line cannot reach the economic scale and excessive production line increases transportation and warehousing difficulty of raw materials and finished goods.

Universal configuration of commercial organic fertilizer production line

As the detailed information on organic fertilizer production process/technology has been carefully introduced in the products page, if you are interested in reading more, Please refer to 50,000 t/y bio organic fertilizer production line

Cow manure organic fertilizer production technology is used for other fertilizer production, like bird manure, chicken manure, sheep manure, pig manure, etc.Cow manure and other byproducts of animal production, if not carefully managed, will have a significant negative impact on the environment. Therefore, cow manure management is important for cattle farms.

For the moment, it is premature to develop cow dung organic fertilizer production in large scale and industrialization. The rapid development of organic agriculture and fertilizer prices continuously rising trend effectively drive organic fertilizer market and growth, which will pose a direct thrust to carry out large-scale cattle manure resource utilization. The improvement, in organic fertilizer processing technology, provides strong technical support for normal operation of the organic fertilizer plant. In addition, a wealth of resources of cow dung provides a stable raw supply for organic fertilizer production.

Extension Reading:

★ chicken manure fertilizer manufacturing process

★ how to process pig manure into top-quality organic fertilizers