—-Get your dream business started

OUTLINE:

»» How to Set, Start Your Business Orientation?

»» Where to Locate?

»» How to Begin Your Production?

One of the agricultural related business opportunities that an entrepreneur can successfully start in any part of the world is to go into the manufacturing of organic fertilizer. Almost everyday, we receive lots of questions on “how to establish an organic fertilizer plant”, “what should I do to start organic fertilizer production business” or “could you please give me your advice on a cost-effective start-up”. Before rushing into something that might make you the most money, there’s a lot to consider.

Actually, we have published a post about Small Scale Organic Fertilizer Production Plant-1 Ton per Hour for organic fertilizer business beginners before! Today, in this article, Allance Fertilizer Machinery will specify a complete guide on how to find the path for you. Hope you could find fun, fulfillment, greater control, AND make lots of money along the way.

How to Set, Start Your Business Orientation?

First of all an entrepreneur has to decide about which product to be manufacture. You can set your business orientation in accordance with your raw material (what organic waste available in your locals?), as there are different types of organic fertilizers you can make and sell. Meanwhile the product should have good demand and availability of customers.

List Of 3 Organic Fertilizer Manufacturing Business Ideas:

1.Municipal solid waste(MSW) organic fertilizer

Due to economic development, industrialization and increasing population, problems related to the expanded consumption and depletion of resources, and the increased output of wide-ranging types of waste are becoming more serious than ever.

In my opinion, production of MSW organic fertilizer is the most complicated waste management method in the world, because a series of processing procedures are included, for example, feedstock receiving and pre-processing, pre-sorting, de-stoning, 35mm screening, 14mm screening, 6mm final screen, crushing & grinding, mixing, composting etc. However, it benefits our environment and community most as management of such discarded wastes is now a challenging tasks in all the urban and semi urban areas specially the task of prompt collection- transportation and disposal.

Previous studies also show that composting of municipal solid waste is more beneficial than other existing options such as land filling, incineration or open disposal. Co-composting with another organic waste, such as faecal sludge is more common, although MSW can be processed alone, as it improves the composting properties, in particular the carbon-nitrogen ratio and moisture content.

Successful Business Case:

The organic compost fertilizer produced at the solid waste treatment plant in Kochi, India

IL&FS Environmental Infrastructure & Services Ltd (IEISL) is one of the most famous composting firms in India. It receives the raw garbage free of cost from municipal authorities, which they process, bag and sell either to fertilizer companies or under their own brands. IEISL operates composting units at Delhi, Jalandhar, Mysore, Kozhikode, Erode, Pollachi, Mettupalayam, Udumalpet and Coonoor that can together process 1,480 TPD(ton per day) of MSW in 2011. This organic fertilizer business is tested to be profitable. By adding MSW compost, not only would the OC in the soils go up, but farmers will also see a dramatic improvement in the nutrient use efficiency of the chemical fertilizers applied by them.

2.Cow manure organic fertilizer

A recent cost-benefit analysis of existing enterprises indicated that the cow dung organic fertilizer business can be profitable because cow manure is a natural and excellent source as a fertilizer. Cow manure causes heavy water and air pollution. However, if raw cow dung is once composted, it can provide numerous benefits to the environment and soil.

The design of cow dung organic fertilizer production line flowchart includes the below considerations:

◆ Gathering cow manure with other bio-degradable agro waste such as kitchen waste, farm residues and forest litter etc.

◆ Advanced material blending technology and windrow composting system or agitated channel composting system;

◆ Reasonable secondary pollution (waste gas and odor) control technology;

◆ Newly designed cow dung compost fertilizer granulation technology and equipment.

Successful Business Case:

COWSMO, INC. locates in S1843 County Road U Cochrane, WI 54622. Cowsmo Compost really is composted manure from their dairy cows. The composting process utilized by Cowsmo meets the National Organic Practices standards for both compost and manure. What amazing is the complete recycling system that Cowsmo, INC. uses in its production of cow dung compost fertilizer.

Here comes the details: Using a flush system, cow manure and used sawdust bedding is removed from the pens. Solid-liquid separation process is done by a screen over which the flush water is pumped. After that, the solids are taken to the compost facility where they are built into windrows for composting >>>click to see the complete process when windrow composting.

◇ Tracking the internal temperatures of the windrows and keeps records on each one from start to finish;

◇ Turning the windrow piles when the correct temperature are recorded;

◇ How to tell the compost is finished or not: when the color changes from yellow to dark brownish-black, the smell changes from that of dairy manure to an earthy soil-like aroma, the composting process is finished.

◇ Bagging the generated compost, and selling them in bags.

Cowsmo compost is not certified organic, but it does meet NOP standards and is widely used by certified organic growers in the region.

3.Vermicompost

Vermicomposting is defined as the production of compost with the use of worms. It is a fast way to convert organic farm waste (decomposing vegetable or food waste) into organic fertilizer. The vermicompost production process uses various species of worms, usually red wigglers, white worms, and other earthworms. Vermicompost organic fertilizer production has become a major component of agro-business models across the world and the commercial production of vermicompost is increasing tremendously by individuals and fertilizer companies due to very low initial investment capital and high returns. An entrepreneur can start this business with the proper know-how of the production process.

Process: Pre-sorted organic material is unloaded into a platform, then stacked in windrow form and allowed to be composted for 3 weeks with weekly turning. After 3 weeks, the material is screened with a rotary screen with 16mm openings. Alternatively, vibroscreen can be used with the same opening. Vermi-beds are prepared in the meanwhile as mentioned above. The semi-composted (pre-composted) material is fed into the vermi-beds.

Uses for vermicompost:

◆ Potting Soil

◆Germination Mix

◆Lawn Dressing

◆Flower Beds

◆Vegetables

Other organic fertilizer production businesses include: pressmud organic fertilizer, sheep manure compost fertilizer, palm oil waste organic fertilizer, biogas residue fertilizer, chicken manure compost fertilizer, pig manure bio fertilizer, winery waste fertilizer, mushroom compost, fish waste compost fertilizer, olive mill pomace compost etc. For large scale producers, it is an added advantage to set the business orientation according to the available main input/cheap raw materials in your locals. In other words, for compost fertilizer programs, your business orientation should be based on what is generated in the community.

Where will the Business be Located?

Starting an organic fertilizer manufacturing company can be considered to be capital intensive, but it is indeed money-spinning business if it is well located.

Here are some facts that you should take into consideration:

☞ Doing your organic fertilizer production projection with the assumption that there won’t be any major competitor offering same products and customer care services as you do within same location. Therefore, before choosing a location, businessmen should conduct a thorough market survey and feasibility studies in order for you to be able to penetrate the available market in your target market location. “that location which,in consideration of all factors affecting products delivered to customers cost of product to be manufactured, will afford the enterprise he greatest advantages obtained by virtue of location”

☞ Mainly rural areas with abundant agriculture and suburbs of towns and cities are ideal for setting commercial composting units. Make sure to establish organic fertilizer production units nearby dairy unites (a commercial dairy farm or large concentration of cattle population for cheap raw materials) if animal waste is your main raw materials. Meanwhile transportation cost would be less in this case.

☞ It is necessary to spent time and resources to conduct the feasibility studies and market survey so as to enable you locate the business in an area that will support the growth of the business and also for you to be able offer much more than your competitors will be offering. Make sure your future location won’t be scattered by several big scale and small scale fertilizer cum organic fertilizer production companies.

☞ Other factors: The Entrepreneur frequently looks for such location where he can attract high level staff and customer willing to pay higher cost for organic fertilizer, and where workers and non-technical people are easily available. Besides this, the facility and availability of laborers, infrastructural facilities like land, transportation, water, govt. offices and administration are weighted high while selecting the location.

How to Start Production?

1. Production Capacity Planning–How Many Ton(s) per Hour/Year to Start with?

Compost fertilizer program capacity is affected by production requirements which are estimated in accordance with types and estimated quantities of feedstock and amendment material, and customer requirements. Determination of the maximum capacity of an organic fertilizer manufacturing facility is important because of the need to ensure that waste received at the site can be processed promptly. The composting process, from receipt of raw feedstock material through to the production of mature compost, typically takes several weeks to complete. This should be considered in all aspects of site design to ensure there is adequate capacity for the quantity of material that will be processed.

For simplicity, the organic fertilizer plants may be categorized according to input waste intake capacity into the following:

(a) Small plants up to 0.8-1 T/H

(b) Medium size plants 30,000-50,000 tons annually

(c) Large plants above 50,000 tons per year

PS: facility design and layout of the above-mentioned plants will be detailed below.

2. Plant Layout Designing -Three Designs for Your Reference

Organic fertilizer plant layout relates to the relative position of fertilizer equipment or units within a given site. Layout determines materials handling, utilization of space, equipment and personnel. Here are 3 examples:

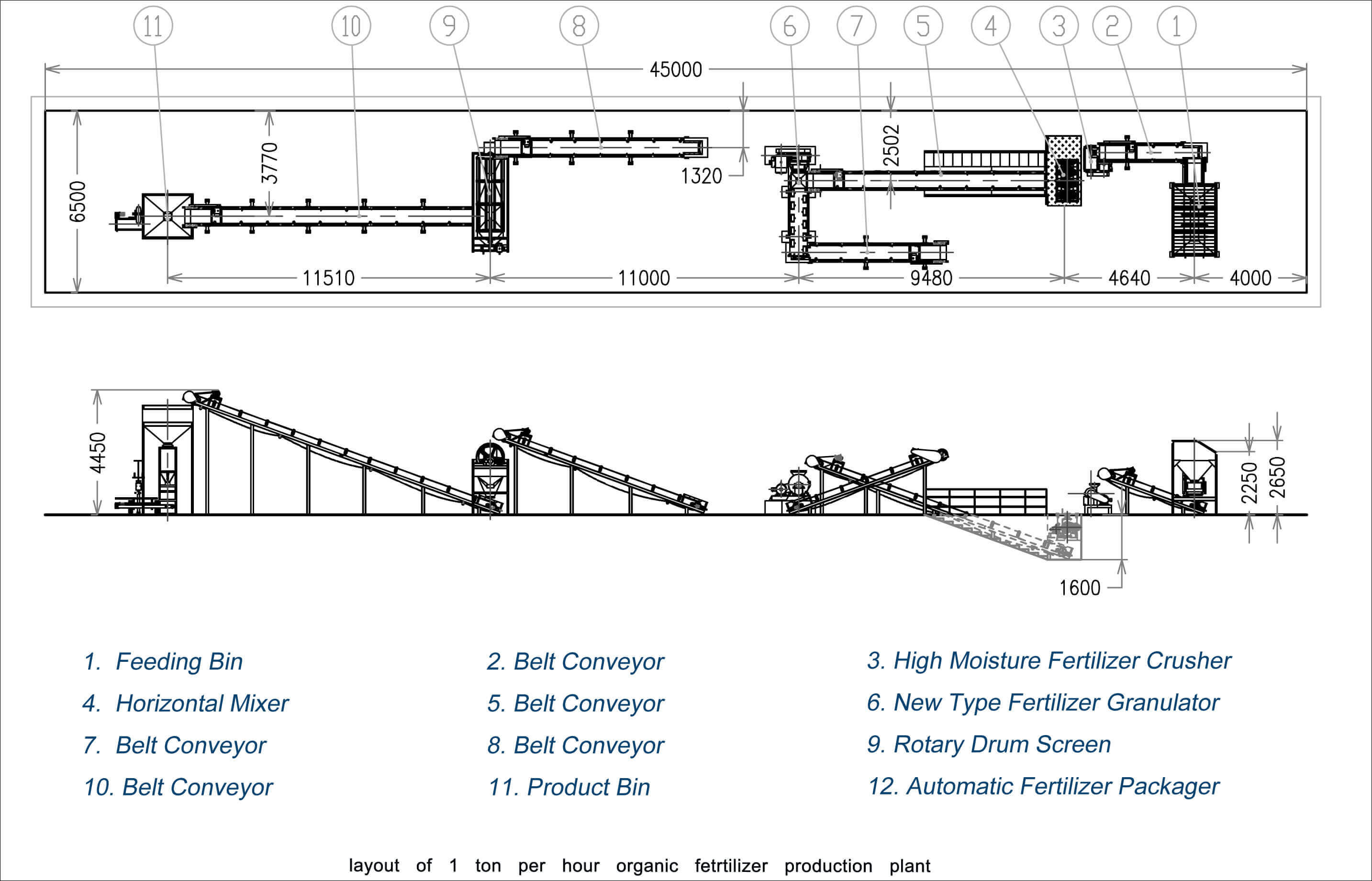

(a) Small Plant with capacity: 0.8-1 t/h

List of equipment for composting, granulation, screening and bagging – capacity 0.8-1 T/H

|

Process

|

Item/Equipment

|

Nos.

|

Technical Parameter

|

|

Composting

|

01 set

|

Model:9ALCFYD-2000 Power:33hp Capacity:400-500m³/h

|

|

|

Crushing

|

01 set

|

Model:ALCLSFS-60 Power(kw):15 Capacity(t/h):1-5

Overall Dimension L×W×H(mm):1000X730X1700

|

|

|

Mixing

|

01 set

|

Model:ALCWSJB-70 Power(kw):11 Capacity(t/h):2-3

Overall Dimension L×W×H(mm):2330X1130X970

|

|

|

Granulation

|

01 set

|

Model:ALCJCZL-60 Power(kw):37 Capacity(t/h):2-3

Overall Dimension L×W×H(mm):3550x1430x980

|

|

|

Screening

|

01 set

|

Model:ALCGTSF-1.2X4 Power(kw):5.5 Capacity(t/h):2-5

Overall Dimension L×W×H(mm):5000x1600x3000

|

|

|

Packaging

|

01 set

|

Model:ALC-DGS-50F Power:1.5kw

Packing pace:3-8bag(s)/min Voltage:380v

Overall Dimensions L×W×H(mm): 820×1400×2300 |

Ps: please visit Optimal Design of Small Scale Organic Fertilizer Production Line to learn more information on complete procedure and process, and functions of every machines.

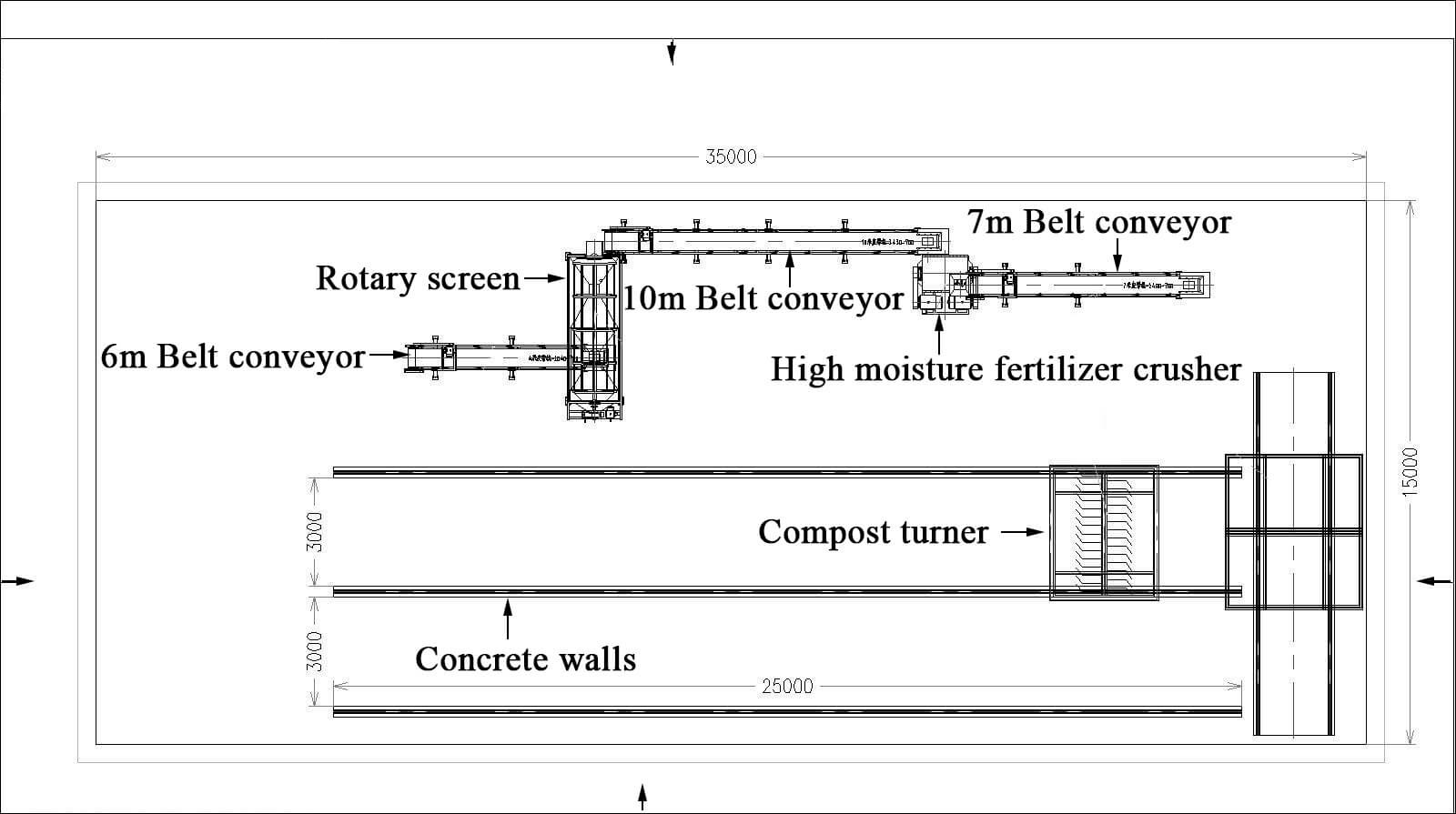

(b) Medium Size Plant with capacity: 30,000 tons annually

|

|

|

| Composting Process | Granulation Process |

List of equipment for pre-processing, granulation, screening and bagging – capacity 30,000 tons per year

|

Process

|

Item/Equipment

|

Nos.

|

Purpose/Role

|

|

Materials preparing

|

All the materials should be prepared in one place, it will be much better to find one place where is open. Materials can be dried under the shine

|

||

|

Crushing

|

High Moisture Fertilizer Crusher

|

01 set

|

There is one high moisture crusher in the line. It can be used in two place. One is here for crushing the raw materials. Why ? Crushed raw materials can be composted better.

|

|

Composting

|

01 set

|

For turning organic waste into compost fertilizer, reducing future environmental problems. with lower power and energy consumption.

|

|

|

Materials store

|

Here you should prepare one place where with shed. Composted raw materials should be stored here for fertilizer processing

|

||

|

Crushing

|

High Moisture Fertilizer Crusher

|

01 set

|

Large size composted raw materials should be crushed first. It will be much better to process powder shape materials.

|

|

Mixing

|

Horizontal Mixer

|

02 sets

|

If needed, you can add some NPK materials here in the mixer. Then these materials can be better mixed.

|

|

Granulation

|

Organic Fertilizer Dedicated Granulator Machine

|

01 set

|

Mixed materials will be sent to the granulator. After granulating, it will be ball shape.

|

|

Screening

|

Rotary Drum Screen

|

01 set

|

There are three outlets in the screen machine. One is for screen the powders out, one is for large size and one is for suitable size.

|

|

Packaging

|

Automatic Organic Fertilizer Packager

|

01 set

|

Suitable size products will be sent to the packing machine. Then pack into bags in your required capacity. The packing weight can be adjusted from 5kg -50kg.

|

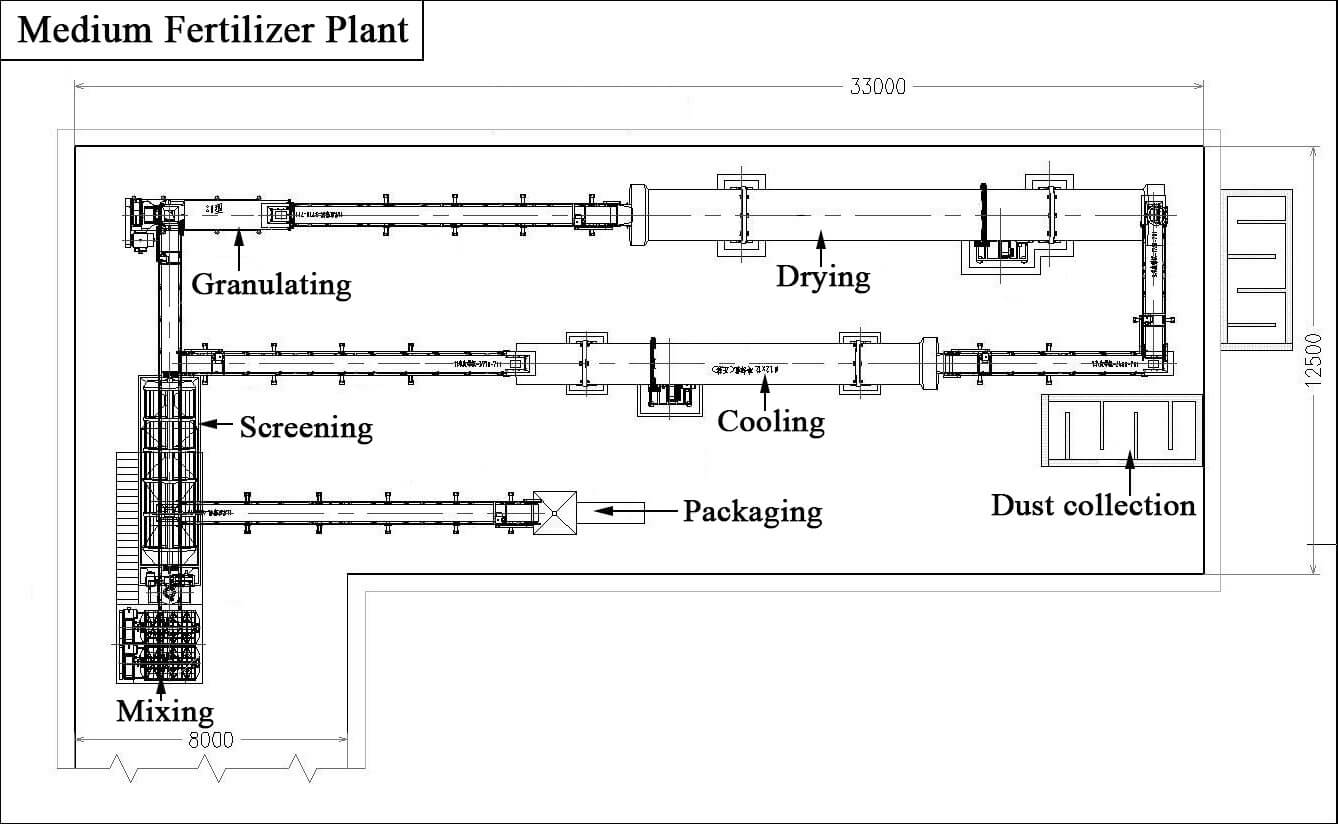

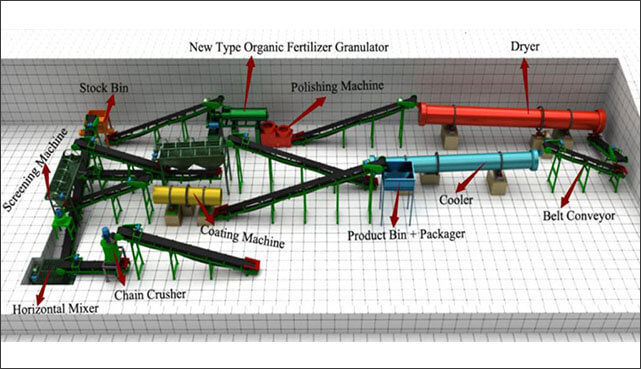

(c) Large Plant with capacity: 50,000 tons per year

List of equipment for pre-processing, granulation, screening and bagging – capacity 50,000 tons per year

|

Sl. No.

|

Item/Equipment

|

Nos.

|

Purpose/Role

|

|

Composting section

|

|||

|

1

|

high-moisture organic waste crusher machine

|

01 set

|

to shred and lower size of organic materials to accelerate the composting speed

|

|

2

|

hydraulic compost turner

|

01 set

|

mechanical pile turning to optimize composting conditions, thus accelerating the process

|

|

3

|

rotary sieve

|

01 set

|

essential for the efficient production of good quality compost as well as in preparation before granulation

|

|

Mixing section

|

|||

|

1

|

belt conveyor

|

01 set

|

to carry the finished compost to mixer machine

|

|

2

|

pan mixer

|

02 sets

|

for mixing additives like nutrient, inoculant etc.

|

|

Granulation section

|

|||

|

1

|

belt conveyor, 12m

|

01 set

|

to convey compost into granulator for further processing

|

|

2

|

newly developed granulated organic fertilizer making machine

|

02 sets

|

to granulate raw materials into round-shape granules

|

|

Drying & Cooling section

|

|||

|

1

|

belt conveyor, 14m

|

01 set

|

for carrying granulated fertilizer into dryer

|

|

2

|

01 set

|

to lower the moisture content of granules

|

|

|

3

|

belt conveyor, 6m

|

01 set

|

to convey organic fertilizer granules into cooler

|

|

4

|

01 set

|

to lower the temperature of granules after drying process

|

|

|

Screening & Packing section

|

|||

|

1

|

belt conveyor, 10m

|

01 set

|

to convey granules into screening machine

|

|

2

|

first grade pre-screening machine

|

01 set

|

for screen sub-standard granules out

|

|

3

|

belt conveyor, 10m

|

01 set

|

for carrying the screened granules to the next sieve

|

|

4

|

second grade rotary sieve

|

01 set

|

for further screening of sub-standard fertilizer pellets

|

|

5

|

belt conveyor, 10m

|

01 set

|

to convey the screened fertilizer granules to the packager

|

|

6

|

automatic packager

|

02 sets

|

for packaging finished products into bags

|

Send your inquiry to get the latest quotation now, or you can mail to info@fertilizer-machine.net