The Design of Non-polluted Natural Organic Chicken Manure Fertilizer Production Technology Process includes that:

1. the technology of composite strains and propagation is efficient.

2. the advanced allocation technology of raw materials and biological fermentation system.

3. the optimal formula technology of special fertilizer(we can use the flexible way by according to the local soil and the characteristic of crop to design the best combination of product formula).

4. the reasonable secondary pollution control technology(exhausted gas and the stench).

5. the complete set of technology equipment of fertilizer making and designing and manufacturing technology.

Organic chicken manure fertilizer production technology process includes the selection of raw material (chicken manure etc)→drying and sterilization→burden mixing→granulation→cooling and screening→measuring and cutting→product storage.

The Complex Organic Chicken Manure Fertilizer Production Technology Process is :

Fermentation of organic materials (animal manure, municipal wastes, crumpled leaves, biogas residue, and abandoned strains etc.); being crushed by semi-wet material crusher; being blended with NPK elements (Pure nitrogen, phosphorus pentoxide, potassium chloride, ammonium chloride, etc) to arrive a certain mineral elements content level; being granulated by new type organic fertilizer dedicated granulator; drying; and screening, during which qualified fertilizer pellets will be packaged with automatic fertilizer packager,

and unqualified ones will be re-crushed and re-granulated.

Among them, what is essential for organic fertilizer production technology process is the rational combination of the raw material fineness. According to our experience, the whole fineness of raw material should be collocated as follow: 100-60 mesh raw materials are account for 30%-40%, the raw materials from 60 mesh to the 1.00mm diameter are account for about 35%, the small particles of the 1.00-2.00mm diameter are account for the 25%-30%, the fineness of material is higher, their stickiness are better, and their

particles surface are more smoothness after granulation. But in their production process, due to the over proportion use of high fineness material, its good stickiness will cause the large and irregular particles problems.

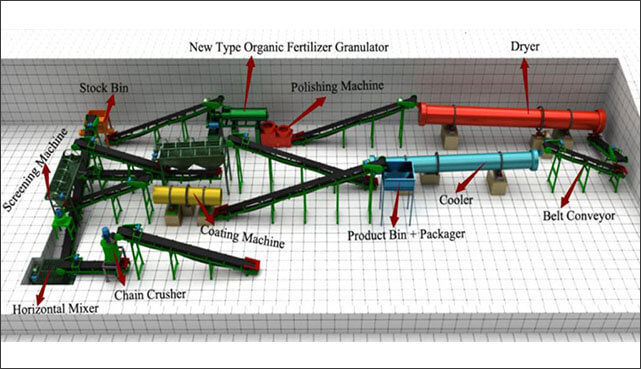

The chicken manure organic fertilizer production technology process is closely linked with the organic fertilizer production line equipment configuration. The general complete set of equipment of the organic fertilizer production line consists of fermentation system, drying system, deodorant dust removal system, pulverizing system, batching system, hybrid system, and granulation system, screening system, and finished product packing system.

Machines Being Equipped in Every Production System:

The fermentation system consists of the feedstock conveyor, biology deodorization machine, mixing agitation, the proprietary lift composting heap turner and the electric automatic control system;

The main equipment of the drying system is belt conveyor, rotary dryer, cooling machine, induced draft fan, hot-blast fan, etc; removing dust and deodorization system is compos of settling chamber and dust chamber, the producer of the fertilizer facilities are provided the free blueprint and give the user free guidance in assembling;

Pulverizing system contains the new type semi-wet material crusher, LP series chain crusher or cage crusher, belt conveyor and so on;

Batching system includes the electronic batching system, disc feeding machine, shaking screen equipment, they can allocate 6-8 kinds of raw materials;

Hybrids system consists of the optional horizontal mixer, disc agitator, shaking screen, mobile belt conveyor;

Granulation system are needed the pelletizer equipment, the selection of the pelletizer equipment contains compound fertilizer roller extrusion granulator, disc granulator, flat die excursion granulator, biology organic fertilizer ball granulator, special organic fertilizer granulator, rotary drum granulator, cast round machine, special compound fertilizer granulator etc;

Screening system are mainly finished by the cylinder round sifter, it can install the primary screening machine, secondary screening machine, to improve the rate of finished product and make the particles better;

Finished product packing system includes the computer quantitative packing scale, stock bin, automatic sack closer and so on. So it can achieve the automatic organic fertilizer production line without block. The scale of the construction for the chicken manure organic fertilizer production line device layout is generally 3-10 ten thousand tons for their annual output. We should take the overall consideration of their local resource, capacity of market, and the situation of the market cap. The scale of investment and project design of the product should according to the following conditions: the character of raw material resource, the local soil condition, the local plantation structure and the main crop variety, the factory site conditions, the automation of production etc.

Extension Reading:

▽ Swine Manure Organic Fertilizer Production Process

▽ Cow Dung Organic Fertilizer Production Technology

▽ Sapropel and Peat Fertilizer Making Technology

Friendly Tips:

If you are a first-time investor, Allance Machinery recommend Small Scale Organic Fertilizer Plant