Development Edible Fungi Industry and Its Value in People’s Daily Life

With the development of human living standard, people’s understanding of edible fungi is also rising. Edible fungi, is commonly known as mushroom, has been consumed for a kind of food and occasionally consumed for supposed medicinal properties at all over the world in the world. Since the middle of the last century, global production of edible fungi industry has been growing. According to recent studies, the international trade volume and consumption of edible fungi is continuously increasing. In 2016, the market value of global cultivation of edible mushrooms is about 30-34 billion dollars and the output value of medical fungi is 10-12 billion dollars, which totally amounts to 40-50 billion dollars. Across the globe, the major producing country of edible fungus are American, Netherlands, China,

French, Spanish, Japan, Korean, etc.

According to the United Nations Food and Agriculture Organization statistics (FAO), in the recent ten years, the average annual growth rate(AAGR) of edible fungi in the world is 5.6%. The above-mentioned shows that the edible industry in the world is developing faster and faster.

Why the edible fungi industry develops so fast in the world?

Firstly, edible fungi has a high edibleness, which is rich in amino acids, minerals, vitamins, protein and other nutrients.

Besides that, edible fungi has high medicinal value, and it is regard as raw materials of various herbs. It has the function of lowering blood cholesterol, and containing substances that enhance the anti-cancer ability of the human body.

Most of all, the spent mushroom compost produced from edible fungi factory has been the major materials for processing organic fertilizer in many developed countries. In recent years, spent mushroom substrate has played a important role in organic fertilizer production.

Table 1 Nutritional components in Fresh Mushroom

|

Content/100g

|

Mushroom

|

|

Protein (g)

|

2.7

|

|

Vitamin A (μgRE)

|

2

|

|

Vitamin B1 (mg)

|

0.08

|

|

Vitamin B2 (mg)

|

0.35

|

|

Vitamin C (mg)

|

2

|

|

Vitamin E (mg)

|

0.56

|

|

Carotene (μg)

|

10

|

|

Calcium (mg)

|

6

|

|

Ferrum (mg)

|

0.92

|

|

Potassium (mg)

|

312

|

Analysis of Processing Spent Mushroom Substrate into Organic Fertilizer

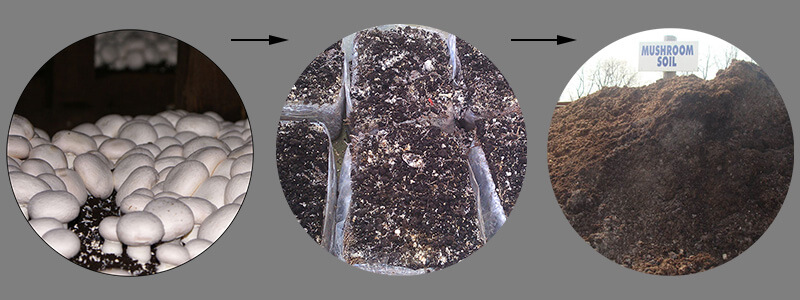

Spent mushroom substrate(SMS), a kind of mushroom residue, produced from mushroom production. For many large mushroom factories, how to deal with the mushroom waste has become an important issue.

Mushroom industrial production is one of the main commercial planting patterns in most developed countries. For example, Netherlands is one of the most advanced countries in the world of edible fungus industry, which can produce 250,000-300,000 tons mushroom in one year. A survey found that a factory produces 10 tons of mushrooms in one day, which means it will produce about 20 tons of spent mushroom substrate.

How does the Netherlands mushroom factory deal with spent mushroom substrate?

There is a clear division of labor in mushroom factory. From the compost production, the construction of plant, to the production of edible fungi, the recycling of the spent mushroom substrate, each step has a corresponding professional company to participate. At the end of mushroom production, lots of spent mushroom substrate have to be handled by factory. They don’t discard the spent mushroom substrate, but use it as one kind of raw material for producing organic fertilizer. Recycle utilization of spent mushroom substrate (SMS) not only achieve the purpose of using local materials, also reduce environmental pollution. In addition, this method has been adopted by more and more countries.

Related research shows that the nutrient content of nitrogen(N), phosphorus (P)and potassium(K) in spent mushroom substrate are higher than these straw and animal manure. Spent mushroom compost also contains large quantities of calcium(Ca), sodium(Na), copper(Cu) and other trace elements, which can be used as a basic material of organic fertilizer.

Spent Mushroom Substrate produced from edible fungi factory

There are some advantages of spent mushroom substrate processing into organic fertilizer:

●A large amount of spent mushroom substrate are processed into organic fertilizer, which can not only reduce environmental pollution, but also realize the effective utilization of resources.

●This mode of recycle utilization significantly reduces the production cost, and improve economic efficiency.

●Compared with other raw materials, spent mushroom substrate contains more organic matters, which can satisfy the requirements of organic fertilizer production.

●Spent mushroom compost has the effect of improving soil fertility and increasing agricultural production.

However, the spent mushroom substrate can’t be used directly because it contains lots of harmful bacteria, insects and weed seeds. Before organic fertilizer production, spent mushroom compost need to be fermented for a long time.

How to Process Spent Mushroom Substrate into Commercial Organic Fertilizer Granule

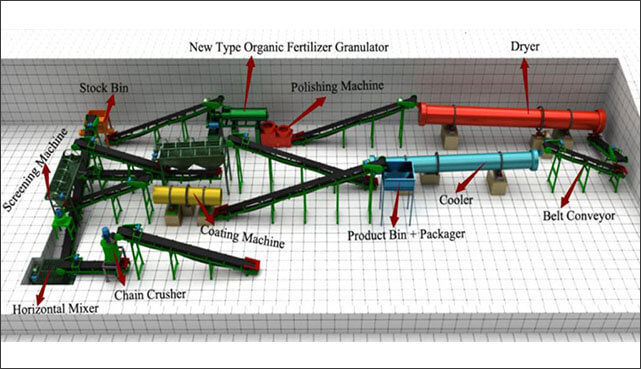

Spent mushroom substrate, a kind of mushroom compost waste, must be managed with a series of specific procedures for organic fertilizer production, which are usually completed by the organic fertilizer production equipment in factory.

1. Composting

For many large fertilizer factories, windrow composting is one of the most convenient methods. The main raw materials for composting are spent mushroom compost, livestock manure, crop straw, and lime.

First, mix the mushroom compost waste with animal manure and lime in a certain proportion. Next step is to allow moisture content to reach 50%-55% by watering the compost pile adequately. At last, pile up the spent mushroom substrate into one-meter-high piles and compost for about 3 weeks. Under adequate water and ventilation conditions, microorganisms in spent mushroom compost can reproduce and degrade organic material, thus produce high temperature that can kill harmful bacteria and weed seeds.

To shorten the production cycle of organic fertilizer, manufactory has to use the Compost Turner Machine to speed up the fermentation time of spent mushroom substrate. After composting, spent mushroom compost need be processed through the next step.

2. Granulating

Granulating is one essential step that directly processes these spent mushroom compost waste into organic fertilizer granule. The granulating process changes the physical property of mushroom compost waste and concentrates multiple nutrients into fertilizer granule. In addition, organic fertilizer granule is more easily to be absorbed by crops, also has the advantage of efficient storing and transporting.

Our company is a well-known manufacturer of organic fertilizer granulator. We can provide various types of fertilizer machine for global customers. In Spent Mushroom Compost Organic Fertilizer Production Process, new type dedicated organic fertilizer granulation machine is used to specially to produce commercial fertilizer granules.

3. Drying &Cooling

When spent mushroom substrate has been processed into granule, the next step is to dry and cool the organic fertilizer granule. In this step, the processed fertilizer granule can be quickly cooled from 65℃-85℃to normal temperature. It can be packaged in time and prevented agglomeration during storage.

Usually, rotary drum dryer & rotary cooler machine provided by us can greatly improve the cooling rate, lower the temperature of organic fertilizer granule and remove part of moisture of fertilizer granule.

4. Screening& Packing

The screening step is is mainly used for separating the finished organic fertilizer granule from the return fertilizer, grading the size of the fertilizer granule, and classifying the finished organic fertilizer granule evenly. Rotary Drum Screening Machine is a common screening equipment in production of organic fertilizer.

Packing is the final step that include automatic feeding, automatic bag feeding, weighing, bagging, sealing and other operating procedures. The organic fertilizer packing machine has the advantages of good packaging quality and stable performance. After packing, the organic fertilizer will be sold in the market.