【ABSTRACT】

▼ Globally Food Waste Problems

▼ Why The Food Waste Could Be Processed into Organic Fertilizer?

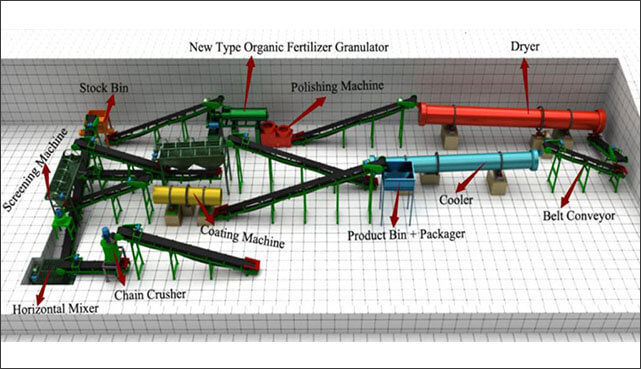

▼ Food Waste into Organic Fertilizer Production Technology & Equipment

▼ Benefits of Food Waste Organic Fertilizer

Food Waste: A Serious Environmental Problem

As the global population increase and the scale of the city expand, the discharge of food waste is always increasing. Each year, millions of food produced around the world, meanwhile millions of tons of food being tossed in the garbage. Nearly 30% of the fruit, vegetables, grains, meat, and packaged foods produced around the world gets tossed out every year. Food waste has become a huge environmental problem in each country.

One survey in 2015 showed that the food waste was more than 1 billion metric tons in China. In Britain, food waste is produced about 15 million metric tons each year. In the U.S., up to 40% of the food produced nationally never gets consumed, about 60 million metric tons of food is wasted and 35 million metric tons of food waste are dumped in landfills every year.

Food waste presents a major challenge in the world now. A large number of food waste has caused serious pollution, it harms climate, water, land and biodiversity. On the one, food waste decomposes anaerobically that will produce greenhouse gases, such as methane, C02 and other harmful waste gases. The carbon footprint of food waste produced is estimated at 3.3 billion tons of greenhouse gases. On the other, food waste is thrown away in landfills that occupies large land, generates landfill gas and floating dust. If the leachate produced in the landfill process is not handled properly, it will cause secondary pollution, which is likely to cause the soil pollution and groundwater pollution.

Incineration and landfill have great disadvantages, if the food waste can be further utilized, it is beneficial to environmental protection and to increase the utilization of renewable resources.

Why The Food Waste Could Be Processed into Organic Fertilizer?

Fruits, vegetables, dairy products, grains, bread, coffee filters, eggshells, meats and newspaper can be composted. Food waste is unique as a compost agent, it is the main source of organic matters. Food waste includes various chemical elements, such as starch, cellulose, protein lipids and inorganic salts, and N, P, K, Ca, Mg, Fe, K some trace elements. Food waste has a good biodegradable rate, which can reach 85%. It has great recycling value with many characteristics, such as high organic matter, high water content and abundant nutrient elements. Food waste has a high moisture content and low physical structure, it is important to mix fresh food waste with a bulking agent that will absorb some of the excess moisture as well as add structure to the mix.

Food waste has high organic content, of which crude protein accounts for 15% to 23%, fat accounts for 17% to 24%, ash accounts for 3% to 6%, Ca accounts for 54% and NaCl accounts for 3%- 4%, etc.

Technology of Turning Food Waste into Organic Fertilizer

From the above, we learn that landfill has low resource utilization rate and pollutes the environment. Some developed countries has established complete food waste disposal system nowadays. For example, in Germany, food waste is mainly treated by composting and anaerobic method, and about 5 million tons organic fertilizer is produced from food waste every year. In British, about 20 million tons CO2 emissions is reduced by composting the food waste each year, and almost 95% cities adopt the composting method in the U.S..

Composting can bring various environmental benefits, including reduction in water pollution, and the economic benefits to farmers, gardeners, and landscapers can be substantial.

◆ Dehydration

Water is the basic component of food waste, accounting for 70%-90%, which is the foundation of food waste spoilage. Therefore, dehydration has become the most important part during the process of turning food waste into organic fertilizer.

The food waste disposal plant is the ideal equipment for processing food waste. It mainly includes: Screen type dewatering system→Feeding system→Automatic sorting system→Solid-liquid separator→Oil-water separator→ In-vessel composter.The basic flow can be divided into the flowing parts:

- The food waste has to be predehydrated firstly because it contains too much swill.

- Remove the inorganic waste in food waste by sorting, such as: metal, wood, plastic, paper, fabric, etc.

- After sorting, the food waste is sent to the Screw type solid-liquid separator for crushing, dehydration and degrease.

- The extruded food waste is dried and sterilized at high temperature to remove the excess moisture and various pathogenic microorganisms. The fineness and dryness of food waste required for compostingare achieved, and the food waste can be sent into the In-vessel composterdirectly through belt conveyor.

- The water removed from food waste is a mixture of oil and water, which is separated by oi-water separator. The separated oil is obtained through deep processing to get bio-diesel or industrial oil.

The set of food waste disposal plant has the advantages of high production, safe operation, low cost, short production cycle, etc. Through the disposal of decrement resource and innocuity about food waste, secondary pollution caused by food waste in transportation is avoided. We have many models of plant for you choose, such as: 500kg/h, 1t/h, 3t/h, 5 t/h, 10t/h, etc.

◆ Composting

In Vessel Composter

In-vessel composter replaces traditional windrow composting technology, is a fully-enclosed fermentation tank adopting with high-temperature aerobic fermentation technology. The fast composting process of the in-vessel composter produces excellent quality compost, and composting can be more closely controlled, leading to faster decomposition and more consistent product quality.

In-vessel composting is insulated, and temperature control is the key factor during composting. A fast breakdown of easily degradable organic matter is achieved by maintaining optimum temperature conditions for the micro-organisms. Achieving a high temperature for inactivating micro-organisms and weed seeds is necessary. The fermentation is kick-started by naturally occurring micro-organisms in the food waste, they break down the compost materials, releasing the nutrients, increasing the temperature to the 60-70ºC needed to kill pathogens and weed seeds, and meet the regulations for processing organic waste. In-vessel composting has the fastest decomposition time, which can compost food waste in as little as 4 days. After just 4-7 days, the compost is discharged, which is odourless, sanitized, rich in organic material, and has balanced a nutrient value.

The odourless, aseptic organic fertilizer produced by composter can not only save the land for filling, protect the environment, but produce certain economic benefits.

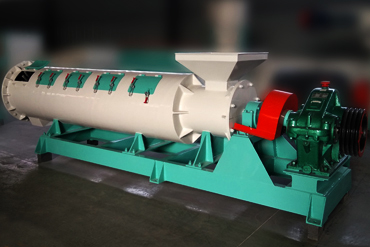

◆ Granulation

Granular organic fertilizers play an important role in fertilizer supply strategies worldwide. The key to improving the yield of organic fertilizer is to choose suitable organic fertilizer granulation machine. Granulation is the process of substance forming into small particles, it enhances substances’ technological properties, prevents caking and increases flow properties, makes possible the application of material small amounts, facilitates loading, transportation, etc. All the raw materials can be made into rounded organic fertilizer through our organic fertilizer granulation machine. The materials granulation rate of can reach 100%, and the organic content can be high to 100%.

Granular organic fertilizers play an important role in fertilizer supply strategies worldwide. The key to improving the yield of organic fertilizer is to choose suitable organic fertilizer granulation machine. Granulation is the process of substance forming into small particles, it enhances substances’ technological properties, prevents caking and increases flow properties, makes possible the application of material small amounts, facilitates loading, transportation, etc. All the raw materials can be made into rounded organic fertilizer through our organic fertilizer granulation machine. The materials granulation rate of can reach 100%, and the organic content can be high to 100%.

For large-scale farming, particle size suitable for the use of market is essential. Our machine can produce organic fertilizers with different size, such as 0.5mm-1.3mm, 1.3mm-3mm, 2mm-5mm. Granulation of organic fertilizer provides some of the most viable ways to blend minerals to create a multi-nutrient fertilizer, allow for bulk storage and packaging, as well as provide ease of handling and application. Granular organic fertilizers are more convenient to use, they are free from unpleasant odours, weed seeds and pathogens, and their composition is well known. In comparison with animal manure, they contain 4.3 times more nitrogen (N), 4 times phosphorus (P2O5) and as many as 8.2 times more potassium (K2O). Granular fertilizer improves the soil viability by increasing humus levels, many soil productivity indicators are improving: physical, chemical, microbiological soil properties and humidity, air, heat regime, and also crop yields.

For large-scale farming, particle size suitable for the use of market is essential. Our machine can produce organic fertilizers with different size, such as 0.5mm-1.3mm, 1.3mm-3mm, 2mm-5mm. Granulation of organic fertilizer provides some of the most viable ways to blend minerals to create a multi-nutrient fertilizer, allow for bulk storage and packaging, as well as provide ease of handling and application. Granular organic fertilizers are more convenient to use, they are free from unpleasant odours, weed seeds and pathogens, and their composition is well known. In comparison with animal manure, they contain 4.3 times more nitrogen (N), 4 times phosphorus (P2O5) and as many as 8.2 times more potassium (K2O). Granular fertilizer improves the soil viability by increasing humus levels, many soil productivity indicators are improving: physical, chemical, microbiological soil properties and humidity, air, heat regime, and also crop yields.

◆ Drying & Cooling

Rotary drum drying & cooling machine are often used together during organic fertilizer production line. The water content of organic fertilizer is removed, the temperature of granule is reduced, achieving the purpose of sterilization and deodorization. The two steps can minimize the loss of nutrients in organic fertilizer, and generate a more smooth boundary.

◆ Screening & Packaging

The screening process is to separate those unqualified granular fertilizers that is completed by the rotary drum screening machine. The unqualified granular fertilizers are sent to be processed again, meanwhile the qualified organic fertilizer will be packaged by automatic packaging machine.

Benefits of Food Waste Organic Fertilizer

Turning food waste into organic fertilizer creates economic and environmental benefits, which can improve soil health, help reduce erosion, and improve water quality. Similarly, renewable natural gas and bio-fuels can be produced from recovered food waste, and their use can help reduce our dependence on greenhouse gas-intensive fossil fuels.

By composting your unwanted food waste, you are energizing the soil for future plant growth. Good quality organic fertilizer will then be used for a wide range of different applications, including agriculture, local farms and in floral displays in public spaces. Organic fertilizer is the best food for soil, of which has many benefits to soil. It is a good source of nutrients for plants, including nitrogen, phosphorous and potassium, as well as micronutrients, which are all essential for plant growth. It can control some plant diseases, also reduce the need for various fungicides and other chemicals.